- Joined

- Jan 25, 2015

- Messages

- 2,558

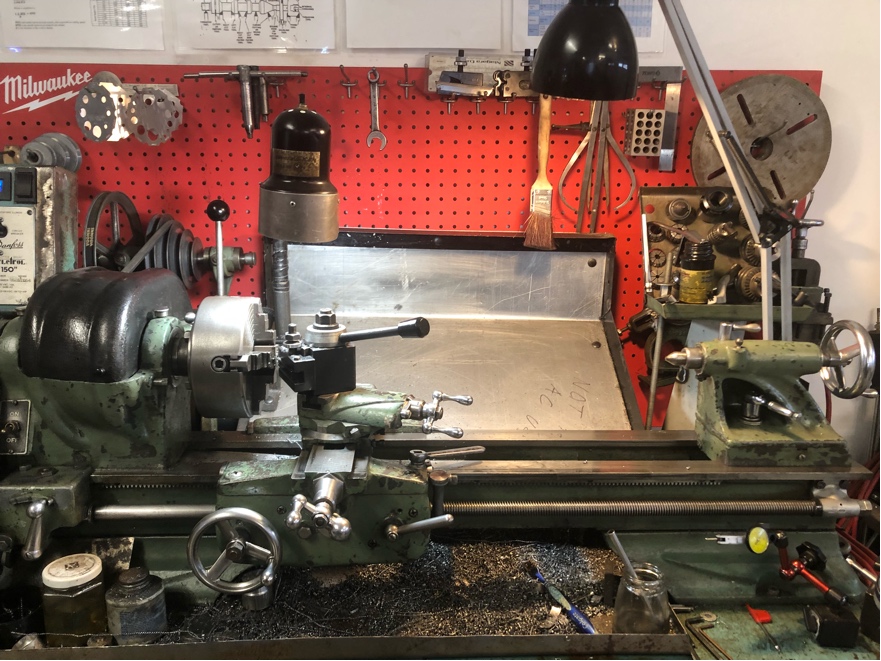

I installed a flex light when I built the cabinet mounting for my Atlas. It worked fine for putting light right on the work spot, But always seemed to want more on areas like dials, tail stock or wherever else I needed to do my work. So I grabbed an "arm light" at the local thrift store. It was super cheap as it was missing it's base and considered "broken".

A little busy work and:

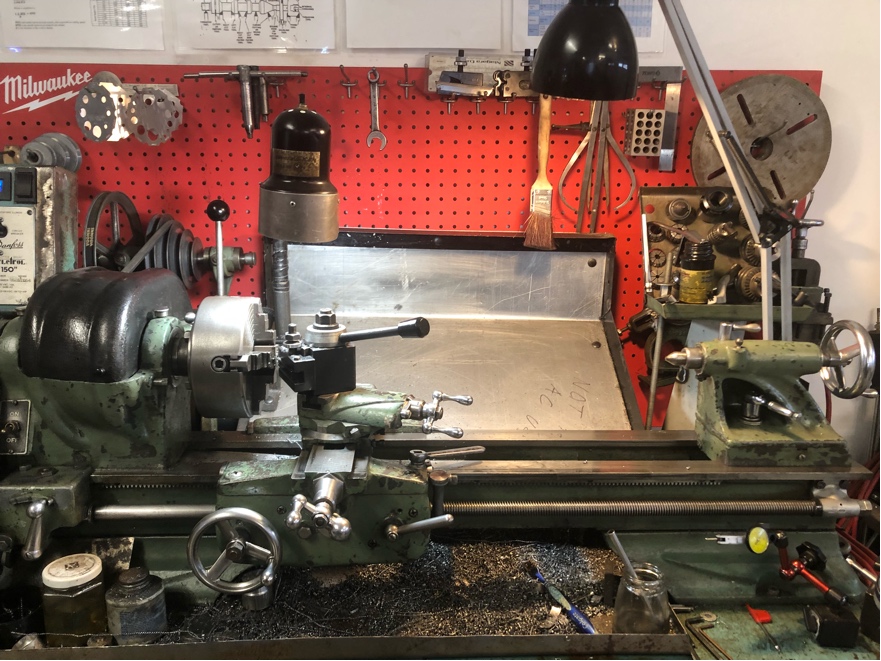

For the mount I just went super simple.:

I just grabbed a piece of scrap square stock, faced it off on both ends, threaded a hole in the bottom, proper sized hole in the top to fit the light base and bolted it through the metal cabinet top. The top is somewhere between 1/8 and 1/4 thick, so the mount is solid. The cabinet already has power, so it was just a matter of plugging the light in.

Works great and I can put extra light right where I need it.

A little busy work and:

For the mount I just went super simple.:

I just grabbed a piece of scrap square stock, faced it off on both ends, threaded a hole in the bottom, proper sized hole in the top to fit the light base and bolted it through the metal cabinet top. The top is somewhere between 1/8 and 1/4 thick, so the mount is solid. The cabinet already has power, so it was just a matter of plugging the light in.

Works great and I can put extra light right where I need it.

Last edited: