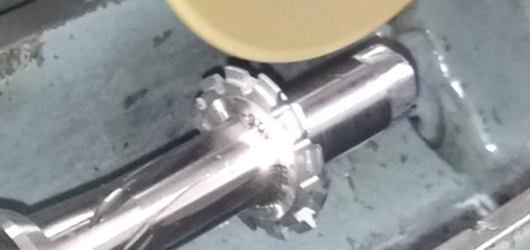

Cutter Sharpening Service Our quality PP Thornton cutters are very durable and cost-effective to sharpen so that you continue to get the best results. £35.00 exc VAT Products Testimonial It may not seem like it to you, but you have a talent that is exceptionally rare in this world. Josh Huether...

ppthornton.com