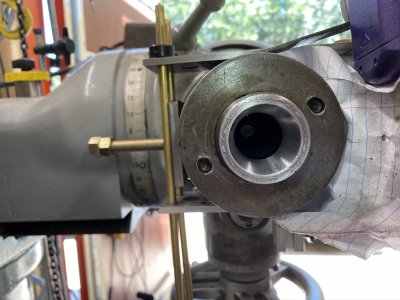

I then used some Dykem red again and checked to see how the colllets mated to the spindle taper. Looked okay. FWIW, after I did this I realized that it would be better to use Prussian Blue and not use collets but instead use a known good taper. A solid taper.

I know that it looks like I’m only getting partial contact of the collet, but from the way the spindle was worn before I started, I could see the same wear pattern. Bottom line is that the collets only make contact on the nose... at least that is what I have read from posts on PM.... posts from guys talking sine, cosine and arcan angle crap. Posts in which the person posting this belief of nose contact appears to be very well informed.

So, I’m under the impression that it looks like the grind came out okay. Of course not perfect. And no where as good as sending the spindle out. But better than it was. And I’m pretty sure I could still get it reground once more if need be. So if I screwed it up, I can still send it out.

I know that it looks like I’m only getting partial contact of the collet, but from the way the spindle was worn before I started, I could see the same wear pattern. Bottom line is that the collets only make contact on the nose... at least that is what I have read from posts on PM.... posts from guys talking sine, cosine and arcan angle crap. Posts in which the person posting this belief of nose contact appears to be very well informed.

So, I’m under the impression that it looks like the grind came out okay. Of course not perfect. And no where as good as sending the spindle out. But better than it was. And I’m pretty sure I could still get it reground once more if need be. So if I screwed it up, I can still send it out.

Attachments

Last edited: