I got a grizzly g0704 yesterday and am planning to convert it to cnc as soon as I can. I don't have any metal machining experience so this should be very interesting. Stay tuned for pictures and videos.

I got Hoss' conversion info and hope that will be enough for me to figure this out.

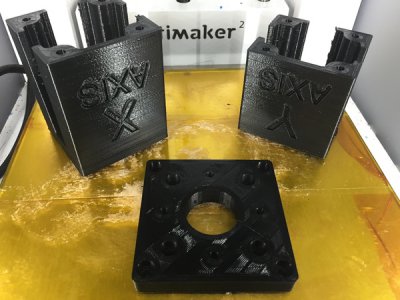

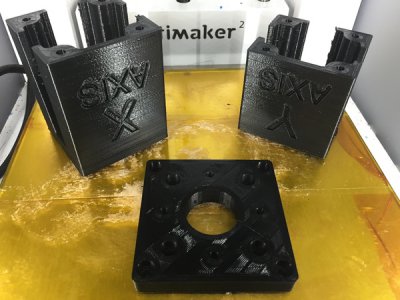

3D printed temporary stepper mounts

I got Hoss' conversion info and hope that will be enough for me to figure this out.

3D printed temporary stepper mounts

Last edited: