I have had a G0768 for about three years. Out of the box I would call it marginal at best. The headstock, motor and mountings, bed, and tailstock appear to be well machined and fit together nicely. However it was many of the minor components that were sloppy as far as fit. Inspite of those problems, I kept the machine and slowly corrected or manufactured those faulty components myself. Incidently, this is my first post on this site.

The major problems I encountered are as follows:

-Unknown to me, the spindle bearings were not seated correctly, ie too loose. This also made for a noisy machine. The overly greased bearings gave out after a few hours of heavy cutting, however replacing them was not difficult. Bought new bearing, and during replacement I slightly reduced the diameter of the left side of the spindle journal to allow that bearing to slide along it with moderate force. Before both were so tight on the spindle you could not get a feel of the pre load on the bearing races.

-The steel saddle plates were replaced with 3/4" milled brass plates. Those gave the saddle nearly a resistance free travel along the bed. I checked the lateral play of the saddle after installing those brass plates and found it less about .0005" but only after I trued up the sliding surfaces of the saddle and compound slide by milling and then lapping the bottom of each slide on a granite slab. Both slides now travel smoothly, with no tight or loose areas along their full travel. Prior to this, the slides were in my opinion, subject to lateral and longitudinal deflection.

-The tail stock clamping plate was poorly machined, which I replaced with a thick circular brass clamping plate. Now it locks like no one's business.

-The idler pivot block was poorly machined causing the idler pulley to be canted. I machined a new pivot block to correct this which also made it easier to adjust the tension of the belts.

The minor issues I corrected:

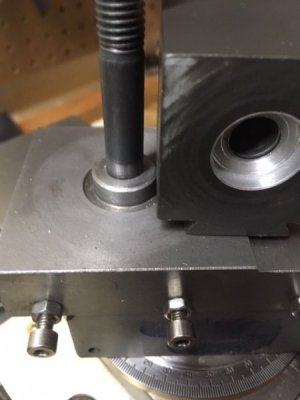

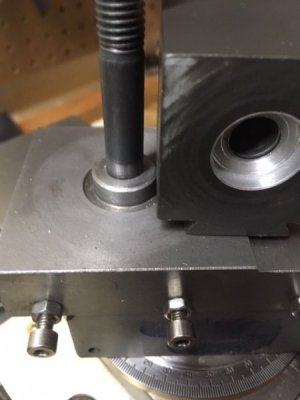

-Mounted a A to Z QCTP. Pressed out the mounting stud and turned a hex head M8x1.25 bolt to press back in. Instead of shimmimg to raise the QCTP above the boss on the slide, I turned the bottom of the QCTP to fit over the boss.

-Raised the tail stock .005"with shims.

-Shimmed the half nut support bar to better align with the lead screw. Operates much smoother.

-Shimmed the gear pivot arm to better align the gear train, and made a few threaded shafts for gear mounts. I intend to make a new pivot arm when time allows.

-Cleaned and greased the gear box and removed metal on one of the gears to make it narrower. This allowed switching from left to right feed much easier.

Replaced the M5-0.8 clamping screws on the compound slide with M8-1.25

Added an accurate stainless degree indicator on the compound slide. By doing so it raised the compound about 0.180". The original plastic one was a joke, a bad one at that. I haven't installed a pointer on it yet.

Other things to consider:

After purchasing this lathe I'm very hesitant to buy another Grizzly product. I considered buying a Grizzly G0704 mill, but instead paid the extra for a PM25MV with 3 axis DRO which I don't regret. Apart from safety shield pivot being too long and the gibs needing adjusting the mill hasen't needed any attention outside normal care.

Knowing what I know now I would have purchased a PM-1022V or PM-1030V lathe. I think Precision Matthews pays more attention to QA on there products. This is a statement from limited knowledge and experience of lathes and mills, so you may have a different opinion.

To sum this up, I spent alot of time thinking and devising methods to correct the stated issues. I think at this point I have a lathe that within it's size is as nearly or as good as the best similar sized lathes out there, but it took a long time to get there.