-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Group Project: Dividing Head - Organization and Design

- Thread starter Shotgun

- Start date

- Joined

- Mar 25, 2013

- Messages

- 4,613

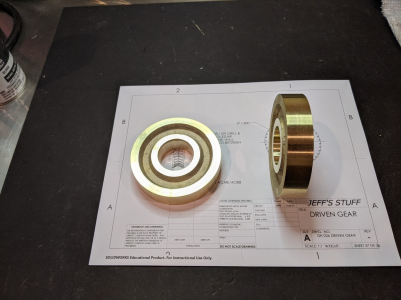

All in all, this is a decent casting. The bottom side looks really good machined:

The top side shows some porosity, which is typically where it shows up:

This porosity should not affect function unless we find larger defects during machining. The blank is now .755" thick. You could take off material and possibly machine out the porosity but it is hard to know how deep you would have to go. I would certainly take 5 thou off the porous side and see if it looks better. There is plenty of room on the diameter to machine it down. I could probably improve over time with better technique and flux. I know I could do better with Everdur if we go that route. Whomever is doing the machining should not expect this to machine like extruded C360. Castings will have smaller more brittle chips.

Someone PM with a mailing address so I can get this to you for the next operation!

Robert

The top side shows some porosity, which is typically where it shows up:

This porosity should not affect function unless we find larger defects during machining. The blank is now .755" thick. You could take off material and possibly machine out the porosity but it is hard to know how deep you would have to go. I would certainly take 5 thou off the porous side and see if it looks better. There is plenty of room on the diameter to machine it down. I could probably improve over time with better technique and flux. I know I could do better with Everdur if we go that route. Whomever is doing the machining should not expect this to machine like extruded C360. Castings will have smaller more brittle chips.

Someone PM with a mailing address so I can get this to you for the next operation!

Robert

Last edited:

- Joined

- Apr 29, 2019

- Messages

- 2,056

Looks pretty good, I do not know much about the intricacies of casting and adding in alloys or fluxes for specific characteristics.

Could the inner and outer rims be made a bit thicker on the top side to allow for the porosity? Although that porosity does not look bad.

The biggest issue will be if our home made hobb can cut that material 8 times. Any sand inclusions will take out the hobb quick. You will need to very clean on the sprue and vents to avoid any loose sand getting into the parts.

But that sure looks like fun.......

Could the inner and outer rims be made a bit thicker on the top side to allow for the porosity? Although that porosity does not look bad.

The biggest issue will be if our home made hobb can cut that material 8 times. Any sand inclusions will take out the hobb quick. You will need to very clean on the sprue and vents to avoid any loose sand getting into the parts.

But that sure looks like fun.......

- Joined

- Mar 25, 2013

- Messages

- 4,613

The porosity is likely gas. I doubt you will see any sand inclusions although that is always possible. There were no sand inclusions on the top surface. Phospho-Cu should remove the gas. There are some other tricks I can try with gating. If any lurkers have some brass or copper they would like to contribute I can improve the alloy. That cast part should have a composition very close to C360.

Robert

Robert

Last edited:

- Joined

- Mar 25, 2013

- Messages

- 4,613

Chips are really not helpful. The surface area to volume ratio is way too large and they just introduce oxides and other impurities into the melt.

Brass and copper have gotten really expensive. I am seeing brass ingots up to $20/lb depending on the material. For some reason Everdur is less expensive and I have seen it for $12/lb. I think Tin has also gotten expensive so maybe that is why.

Robert

Brass and copper have gotten really expensive. I am seeing brass ingots up to $20/lb depending on the material. For some reason Everdur is less expensive and I have seen it for $12/lb. I think Tin has also gotten expensive so maybe that is why.

Robert

Last edited:

- Joined

- Mar 25, 2013

- Messages

- 4,613