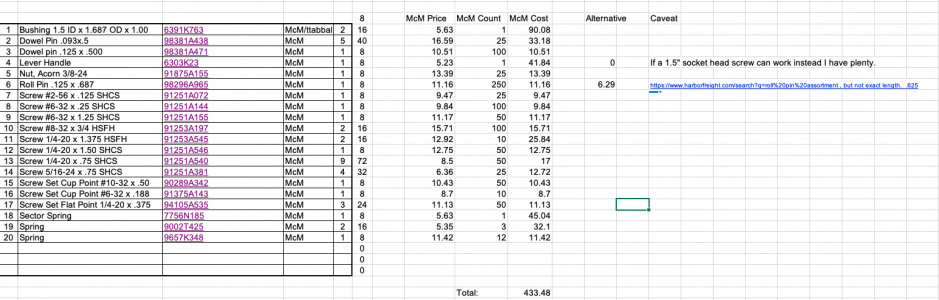

I think this is interesting enough to share. It feels like I'm back at GE doing a "cost-out", where accountants went to work on a product after it was designed and tested to figure out a way to make it cheaper.

The biggest cost by far is the bushing.

@ttabbal , you said you might be able to make that. How do you think that is looking?

The the Sector Springs. I don't think we're going to get out of that one.

The Lever Handles, though. Do we really need it to be 2.5" long? I have some 1/4" cap screws. 1.5" shank, and then an 1" of thread. I could round the heads into a ball. What say ye?

I've got the roll pins, if you .625 length is ok, and you guys don't mind HF roll pins.

I'm currently looking for screw assortments to see if I can get the different sizes in one pack.

View attachment 366610