- Joined

- Aug 13, 2020

- Messages

- 1,342

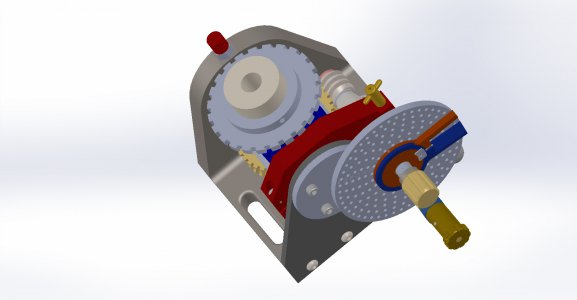

Looking at the model you sent a few days back: The graduations for the Trunnion angle disappear into the slot at about 70 degrees. That was without the Quick Index Plate installed. With it installed, could we roll those graduations toward the zero and put a pointer on the inside of the Main Base?