-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

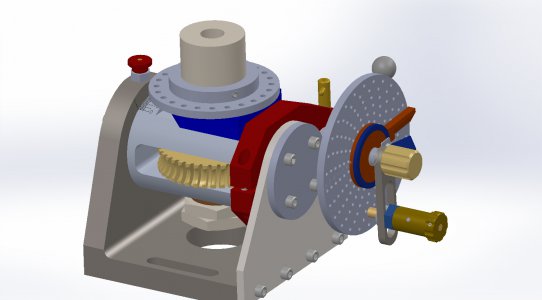

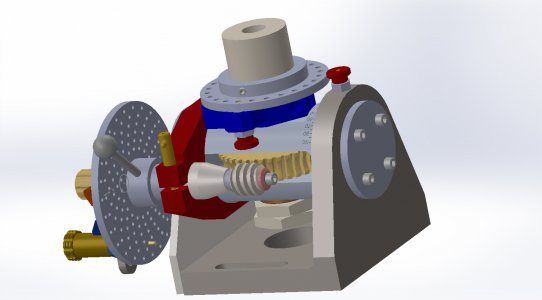

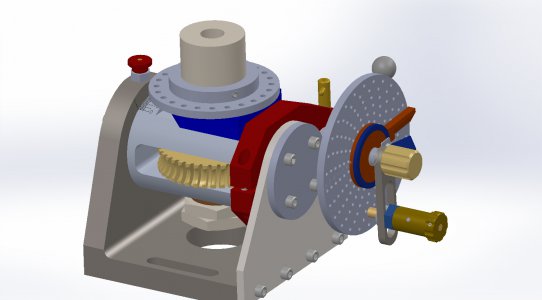

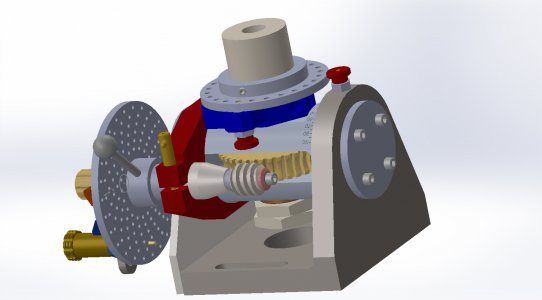

Group Project: Dividing Head - Organization and Design

- Thread starter Shotgun

- Start date

- Joined

- Apr 29, 2019

- Messages

- 2,056

I have a southbend so id like to have the nose with enough material for a chuck from that.

I don't have a South Bend, I need to know how much material you need in the nose.

How much length do you need for a 1.5-8 spindle nose?

M50 is a bit smaller than 2 inches so that should work. How much length is needed?

How much total spindle length do you need for an R8 and draw bar?

See the theme here, I am trying to get numbers for how big do you want it?

MOAR BIGNESS!

M50 needs about 3/4" of threads. Maybe 1" total. Probably similar for a threaded chuck.

R8 will fit diameter wise. Total collet length is 4". Drawbar would just need enough room to draw the collet in. 1/4" is likely more than enough.

I don't have any specific needs, just putting ideas out there that might be helpful.

- Joined

- Apr 29, 2019

- Messages

- 2,056

My Mill is a Z collet and my lathe is a D1-4. So my needs are probably different that anyone else. Anything other than what I have, I have no idea how big it is until someone tells me.

I have started the process of making the drawings and deciding tolerances.

I have started the process of making the drawings and deciding tolerances.

The other thing is if there is a more popular size that everyone else has then i can always make an adaptor if i needed like others are saying. I just havent been able to play with my lathe to know how much material would be needed. I know 2" in diameter would prob be okay for me but idk the length needed on the nose.

- Joined

- Nov 24, 2014

- Messages

- 3,152

You can solve this problem.The other thing is if there is a more popular size that everyone else has then i can always make an adaptor if i needed like others are saying. I just havent been able to play with my lathe to know how much material would be needed. I know 2" in diameter would prob be okay for me but idk the length needed on the nose.

Open a new thread in - - - South Bend FORUM - - - . "I have a ________ (model, size) lathe with a 1.500-8 spindle thread. I don't have access to the late right now but I need to know how long the spindle snout is (including, thread, registration diameter and flange). Can someone please post a picture with a scale sitting on top of the spindle nose? Thank you."

- Joined

- Aug 13, 2020

- Messages

- 1,342

Any chance you could share the solidworks files for me to play with? Give everyone a chance to give last minute input before it goes to drawings?My Mill is a Z collet and my lathe is a D1-4. So my needs are probably different that anyone else. Anything other than what I have, I have no idea how big it is until someone tells me.

I have started the process of making the drawings and deciding tolerances.

- Joined

- Apr 29, 2019

- Messages

- 2,056

Here are some files to play with.

There are 49 Solidworks Files involved at about 30M in size.

I still have a few small details to deal with yet.

Just because it is starting to go to paper does not mean that I can not make changes. I expect changes after I get all the drawings done and I can talk to each person about the parts they are making.

There are 49 Solidworks Files involved at about 30M in size.

I still have a few small details to deal with yet.

Just because it is starting to go to paper does not mean that I can not make changes. I expect changes after I get all the drawings done and I can talk to each person about the parts they are making.

Attachments

Last edited: