- Joined

- Jul 30, 2022

- Messages

- 33

Hi all,

For context around my questions, I'm a complete newb to machining.

I picked up a Johansson/Clausing 8520 mill a few days ago and I'm going through it checking bearings, etc.

I would like some guidance/advice on these two items please.

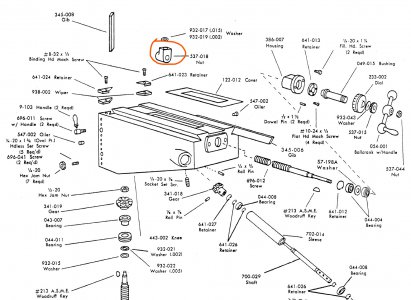

1. The leadscrew and nut for Y travel are very worn (.052 backlash and visually the threads don't look like acme anymore). I'll call Clausing about replacement parts, but I'm concerned that the nut on my machine doesn't resemble the one in the attached drawing. Does the nut in the attached pics look standard/correct?

2. When I got it the Y travel was very tight on the ends of the travel and moved OK in the middle. I'm thinking that's because the way is worn and the gib was over-tightened to compensate. I'm hoping it's because there was gunk buildup on the ends of the travel. I cleaned a lot of gunk from it, but I'd like to know if it needs grinding/scraping before I reassemble it. Is there a way I can measure to determine this?

Thanks

BTW, some context on the general condition of the mill: the bearings were mostly worn out and the spindle had the wrong kind, so I'm replacing them all. The wiring was funky and had the power switch on the knee so I'll redo that. A previous owner cobbled up a strange motor mount to use a longer belt. The base was replaced with a homemade angle iron stand. It had a dried up hornet nest where the quill gears should be. It was painted white (not painted well).

For context around my questions, I'm a complete newb to machining.

I picked up a Johansson/Clausing 8520 mill a few days ago and I'm going through it checking bearings, etc.

I would like some guidance/advice on these two items please.

1. The leadscrew and nut for Y travel are very worn (.052 backlash and visually the threads don't look like acme anymore). I'll call Clausing about replacement parts, but I'm concerned that the nut on my machine doesn't resemble the one in the attached drawing. Does the nut in the attached pics look standard/correct?

2. When I got it the Y travel was very tight on the ends of the travel and moved OK in the middle. I'm thinking that's because the way is worn and the gib was over-tightened to compensate. I'm hoping it's because there was gunk buildup on the ends of the travel. I cleaned a lot of gunk from it, but I'd like to know if it needs grinding/scraping before I reassemble it. Is there a way I can measure to determine this?

Thanks

BTW, some context on the general condition of the mill: the bearings were mostly worn out and the spindle had the wrong kind, so I'm replacing them all. The wiring was funky and had the power switch on the knee so I'll redo that. A previous owner cobbled up a strange motor mount to use a longer belt. The base was replaced with a homemade angle iron stand. It had a dried up hornet nest where the quill gears should be. It was painted white (not painted well).

Attachments

Last edited: