- Joined

- Jun 12, 2018

- Messages

- 712

I just had an idea... lemme know if it's any good or not.

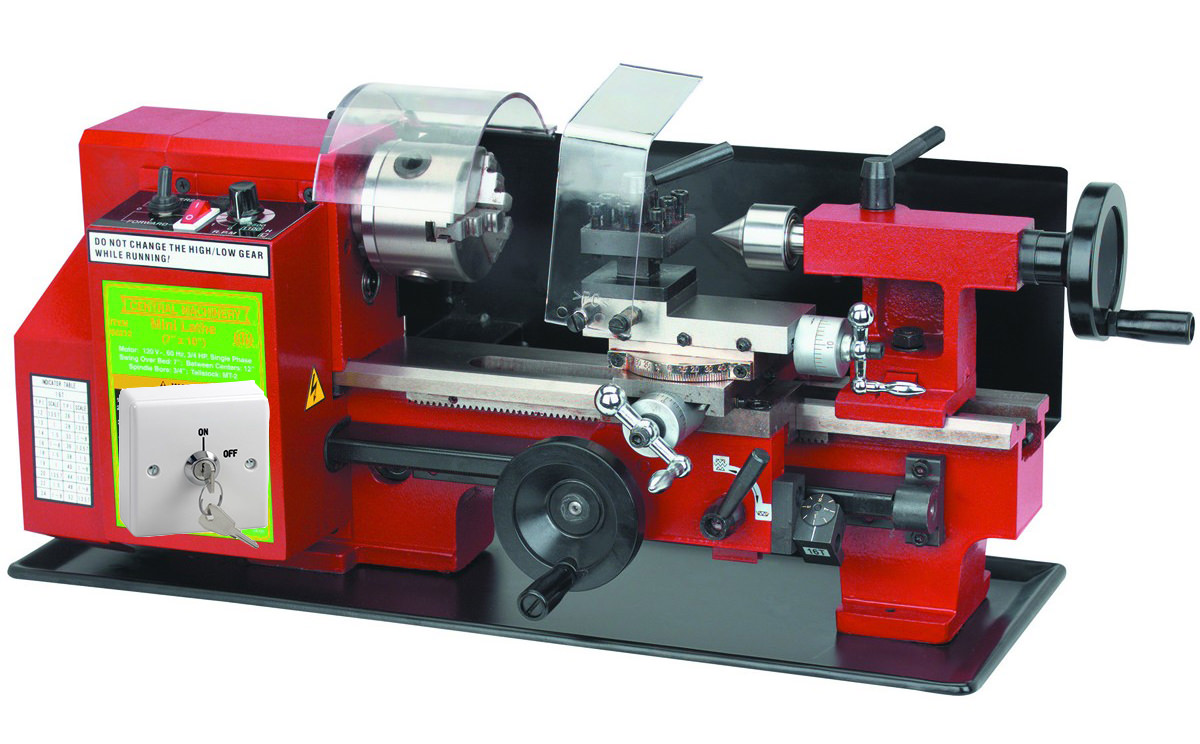

I'm new to this hobby. I ordered my lathe, but I haven't received it yet. Hopefully I'll have it by Tuesday, so I dunno if this has been tried before or not.

I"ve been watching a ton of lathe how-to videos on Youtube and there's one recurring theme about safety. Never leave the chuck key on the chuck. The plastic guard is a good idea.. preventing the operation of the machine if the key is still on the chuck.

My idea is.. why not install a key switch on the machine with the switch key machined/welded on the chuck key? Put a key switch on the machine that you can't pull out while the lathe is in operation.

Wire the main hot wire coming into the key switch, then the outgoing wire to wherever the original hot wire goes to.

Install the key switch to where it's not in the way. Sorry for the poor photoshopping skills.

The power to the machine will not operate without the key in the switch and there will be no power to the machine if the chuck key isn't inside the switch.

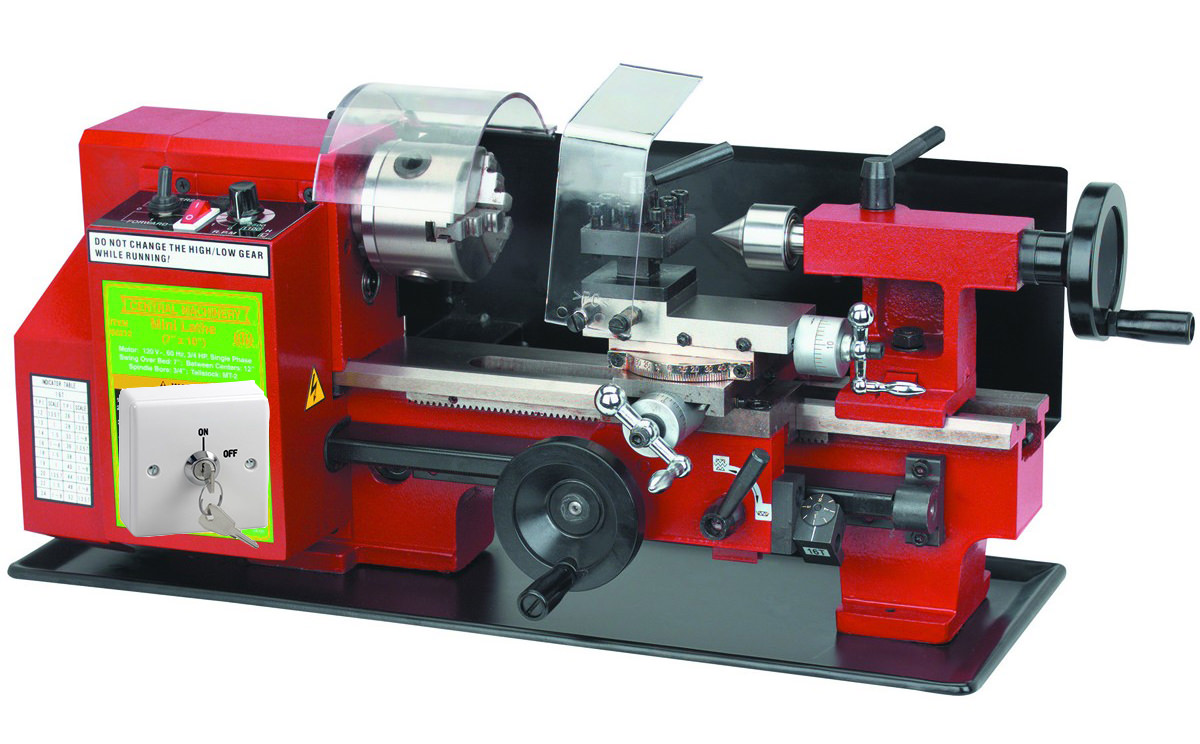

I'm new to this hobby. I ordered my lathe, but I haven't received it yet. Hopefully I'll have it by Tuesday, so I dunno if this has been tried before or not.

I"ve been watching a ton of lathe how-to videos on Youtube and there's one recurring theme about safety. Never leave the chuck key on the chuck. The plastic guard is a good idea.. preventing the operation of the machine if the key is still on the chuck.

My idea is.. why not install a key switch on the machine with the switch key machined/welded on the chuck key? Put a key switch on the machine that you can't pull out while the lathe is in operation.

Wire the main hot wire coming into the key switch, then the outgoing wire to wherever the original hot wire goes to.

Install the key switch to where it's not in the way. Sorry for the poor photoshopping skills.

The power to the machine will not operate without the key in the switch and there will be no power to the machine if the chuck key isn't inside the switch.