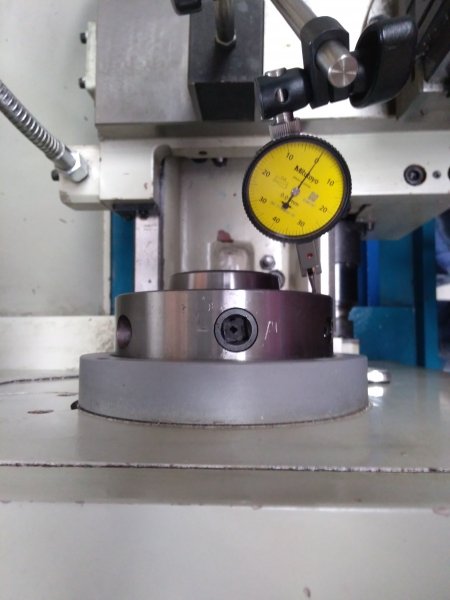

Looking for a second opinion. I suspect the head stock is not lined up down the bed. I do not think it's cross slide as I have faced 3" aluminium and if the cross slide was not perpendicular to the ways I would machine a concave especially with this amount of slew nearly 0.10mm or 0.0035".

My lathe is adjustable but I decided to sleep on it before diving in and adjusting the head stock.

My lathe is adjustable but I decided to sleep on it before diving in and adjusting the head stock.