I'm monkeying around with making a scraper to repair the cross-slide on the 1440 and would appreciate some input from those that use them.

I'm attempting to do this with materials that I have on-hand. The lathe crapped out at very a inconvenient time.

I had to take a pass on a decent bit of side work because with the stick-slip, I messed up the first three pieces. So the budget is hurting.

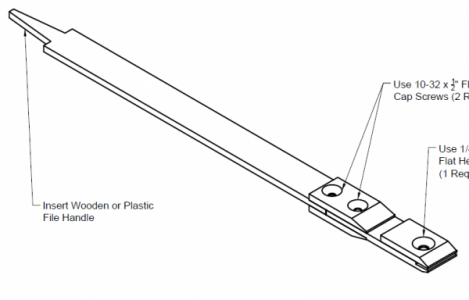

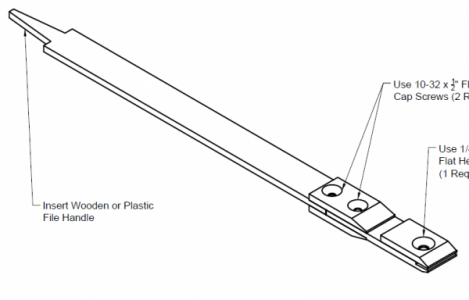

Richard sent me a copy of Keith Rucker's design. (Thanks Richard!)

I have a couple of questions about the design.

I've got a few pieces of 3/4" Sqr. carbide inserts that I'm trying to make do with. I realize that they are really not wide enough, however it's all I've come up with.

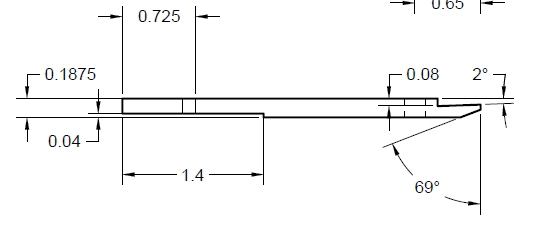

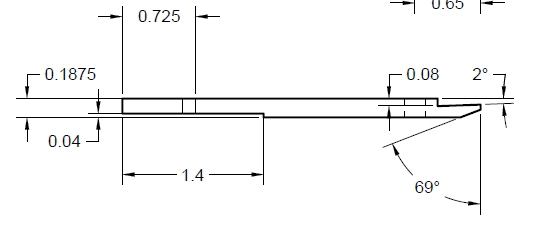

On Keith's design on the insert extension piece, the flat on the end is at 2° positive.

Does anyone know why? I'm wondering if it can be 'straight'.

..........

..........

Here's my first take on it using the 3/4" insert.

I'm making a couple of needed ergonomic / handling modifications to it.

I made up a mock-up out of a file and then played around with it trying to mimic the way I've seen people handle them in videos.

A problem/difficulty has cropped up from this, with my left hand tendons messed up from some medicine, gripping the scraper becomes uncomfortable after a bit.

With this first take, I've made a change on the handle end so that I can try out different size handles if needed. They will be screw on.

My Left-Handed/Right-Handed -ness is odd. I write left handed but do a number of other things right handed, it just depends.

I haven't figured out which way I'll hold a scraper yet.

If I'm holding the end with my left hand, 1.5"-2" DIA. feels best and lessens the discomfort.

Then I've also added a 'Grip' handle for holding the shank left handed.

Thanks,

_Dan

I'm attempting to do this with materials that I have on-hand. The lathe crapped out at very a inconvenient time.

I had to take a pass on a decent bit of side work because with the stick-slip, I messed up the first three pieces. So the budget is hurting.

Richard sent me a copy of Keith Rucker's design. (Thanks Richard!)

I have a couple of questions about the design.

I've got a few pieces of 3/4" Sqr. carbide inserts that I'm trying to make do with. I realize that they are really not wide enough, however it's all I've come up with.

On Keith's design on the insert extension piece, the flat on the end is at 2° positive.

Does anyone know why? I'm wondering if it can be 'straight'.

..........

..........

Here's my first take on it using the 3/4" insert.

I'm making a couple of needed ergonomic / handling modifications to it.

I made up a mock-up out of a file and then played around with it trying to mimic the way I've seen people handle them in videos.

A problem/difficulty has cropped up from this, with my left hand tendons messed up from some medicine, gripping the scraper becomes uncomfortable after a bit.

With this first take, I've made a change on the handle end so that I can try out different size handles if needed. They will be screw on.

My Left-Handed/Right-Handed -ness is odd. I write left handed but do a number of other things right handed, it just depends.

I haven't figured out which way I'll hold a scraper yet.

If I'm holding the end with my left hand, 1.5"-2" DIA. feels best and lessens the discomfort.

Then I've also added a 'Grip' handle for holding the shank left handed.

Thanks,

_Dan