- Joined

- Nov 2, 2014

- Messages

- 21

What quality capacitors were installed to replace the originals?

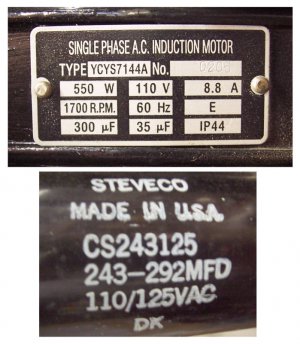

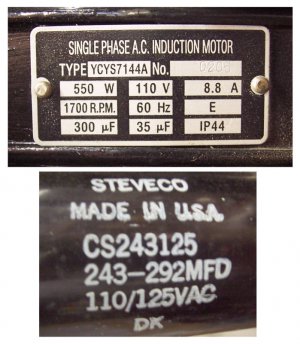

I'm not sure who that question was directed at, but here's my motor & cap spec.

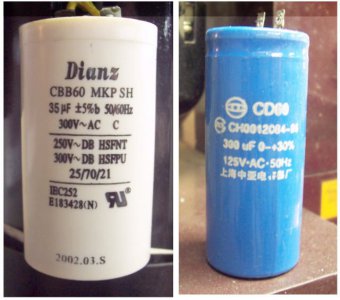

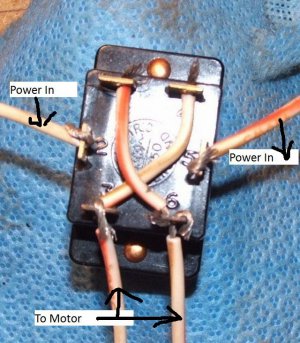

Two motors; one for lathe, one for mill. Same model motor, each has two caps [start/run]. I'm not an electrical guy, this cap was installed by a garage electrician. It works, but I've been unable to find this cap on the Net. I'd like to get a few spares before I convert to a Baldor setup.

Two questions:

(1) Would the start cap be the same as the run cap?

(2) Is a 2-cap motor 'better' than a 1 or 0 cap motor?

Thanks for your help!