- Joined

- Apr 26, 2021

- Messages

- 19

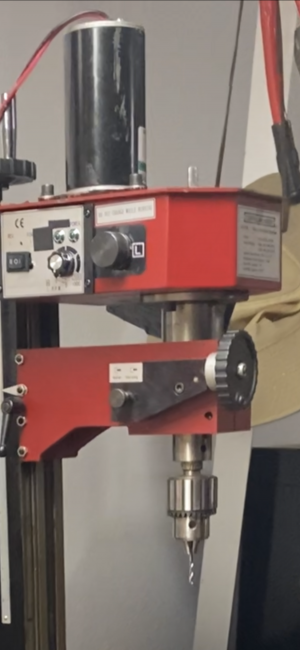

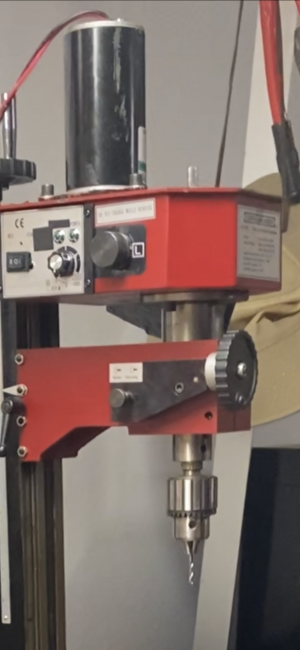

Hey there. I am sure you’ve already finished you modification if you decided to do this, but absolutely you can upgrade the motor. I have changed the drive system twice on my HF mill because the original motor failed and I was dissatisfied with the gear driven transmission. Here are the iterations: replacement motor, replacement motor with belt drive, and upgraded replacement motor with V belt drive pulleys and idler.Well, I’m new to this forum and to machining, so please try to be understanding when I ask stupid questions... here’s the first one. I just bought an HF mini mill (model 44991) and just happen to have a Shop Fox mortising machine that I no loner use/need. It has a 3/4 hp, 8 amp, 3450 rpm motor that I’d like to put on the mini mill. Whattaya think? Am I crazy, or can this work?