After reading many comments on this and other forums I decided to get an 8 x 14. I have made a few parts but I put most of my time getting it set up. I did take much of it apart and clean it up and stone the gibs but i do not think it needed to be done. the r & r did give me more familiarity with the tool. I have not use a lathe in many years so it is new to me but it has been a better than expected experience.

One of the biggest parts of buying this tool is that I want to do ever mod that everyone has done and then some. I finally settled on getting it to a point I can use it for my needs of making simple parts out of .

What I made

Thank you to everyone that has been contributing to these forums you have been so helpful in so many ways

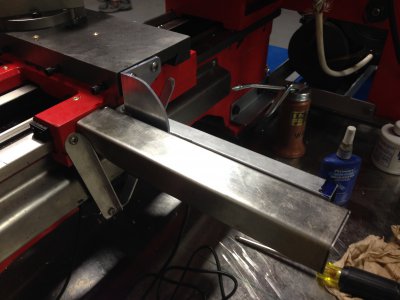

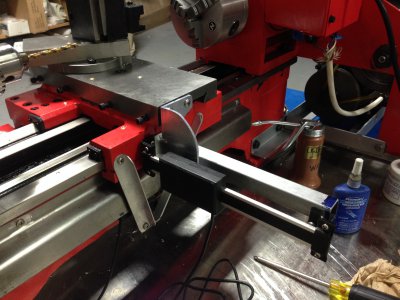

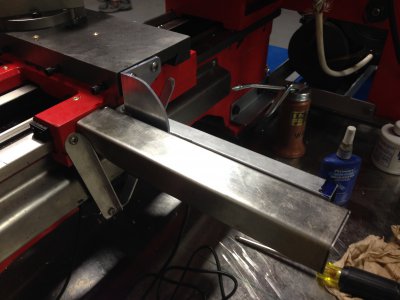

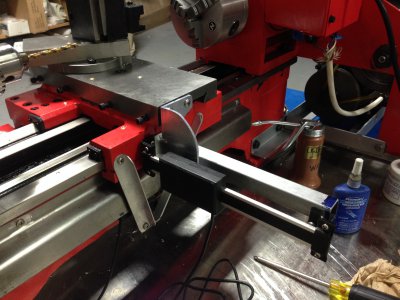

ps. That is a tail stock v block i am working on now

One of the biggest parts of buying this tool is that I want to do ever mod that everyone has done and then some. I finally settled on getting it to a point I can use it for my needs of making simple parts out of .

What I made

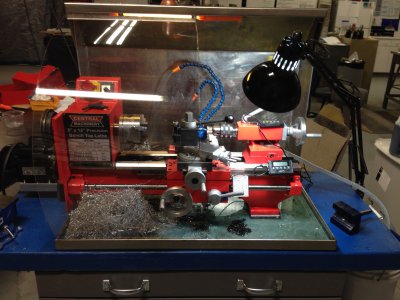

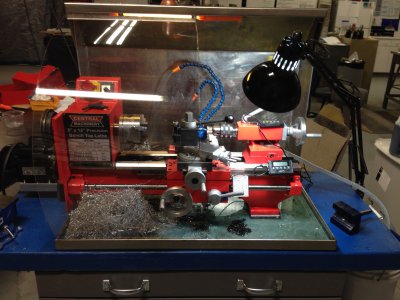

- Bench - legs were laying around. Made the top out of 2x6s sandwiched between plywood on top and bottom. drawers are all 3/4 plywood and I used 2 sets of 100# full runners on the large drawers 200# capacity

- Coolant system - bought a mag base and the flexible nozzles (the expensive part) used a 5 gal bucket an old marine bilge pump and a small transformer that was laying around (like a toy or electronic charger) I through in a small piece of oil boom to soak up any stray oil. I screwed the pump to check of steel to keep it aft the bottom and to make sure it sat in place

- drip pan and back splash - friend gave me a sheet or stainless and i bowered a heavy duty break. it took quite a bit of planning to make the back splash. the lath is bolted down 1/8" out of level so that I need to adjust the table to level the lathe this helped with the coolant running to the tray drain.

- Lexan shield.- It was already cut the right length i just notched it out to make it a little easier to get close to the chuck. The shield comes in hand when coolant gets on large diameter parts

- DRO - cheap +-.003 units they work for what i am doing. I have found to be at least to the tolerance advertised. I made very rigid mounts for them with covers.

- Motor moved- I put the motor on the outside of the machine so that it does not get covered with coolant. this was a little tricky but not too bad

- Lights- mounted cheap harbor freight Florissant light under hood and then desk lamp to side

- Other - cheap vise to cut stock with. drawer dividers from amazon and I really like the place to hand the chip brush in close reach

Thank you to everyone that has been contributing to these forums you have been so helpful in so many ways

ps. That is a tail stock v block i am working on now