- Joined

- Nov 25, 2015

- Messages

- 335

Hey everyone, quick question.

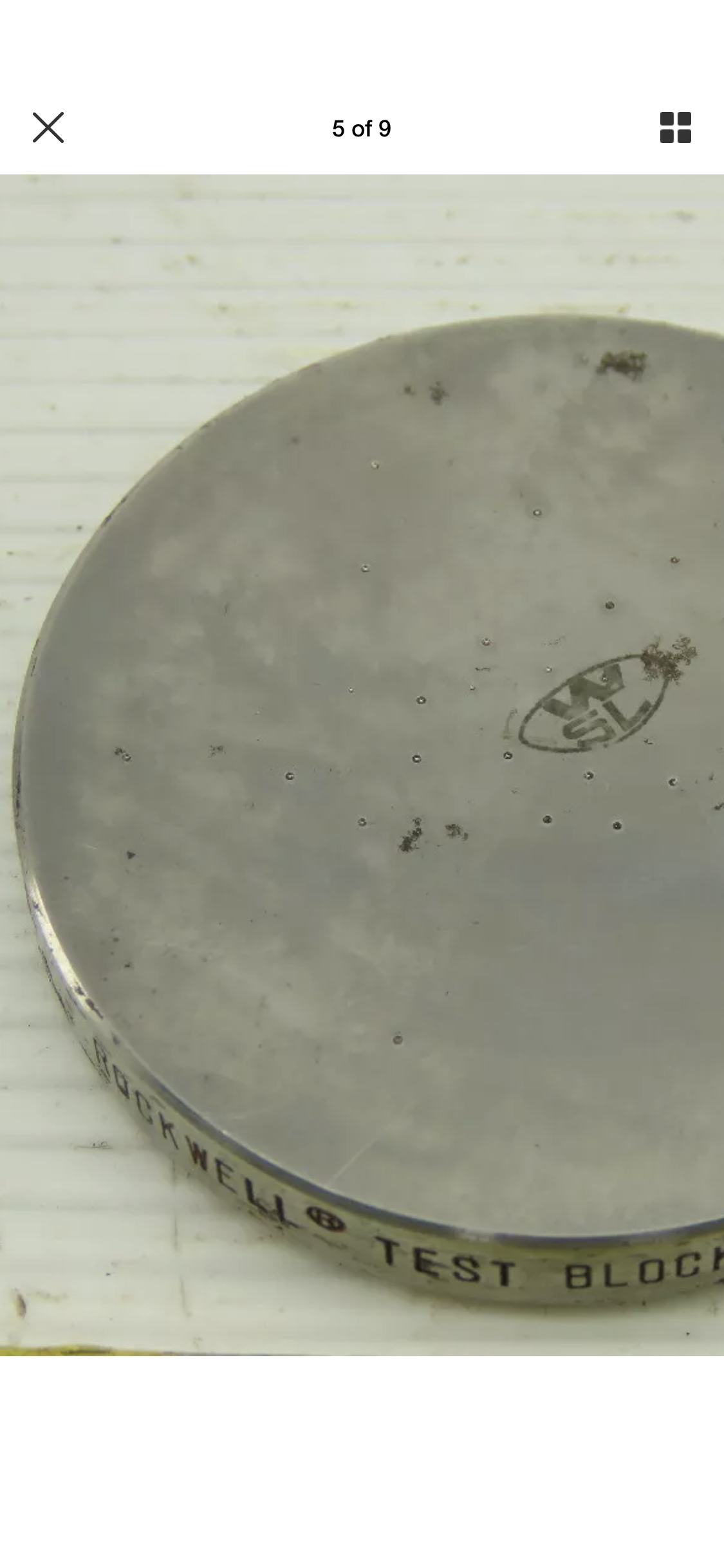

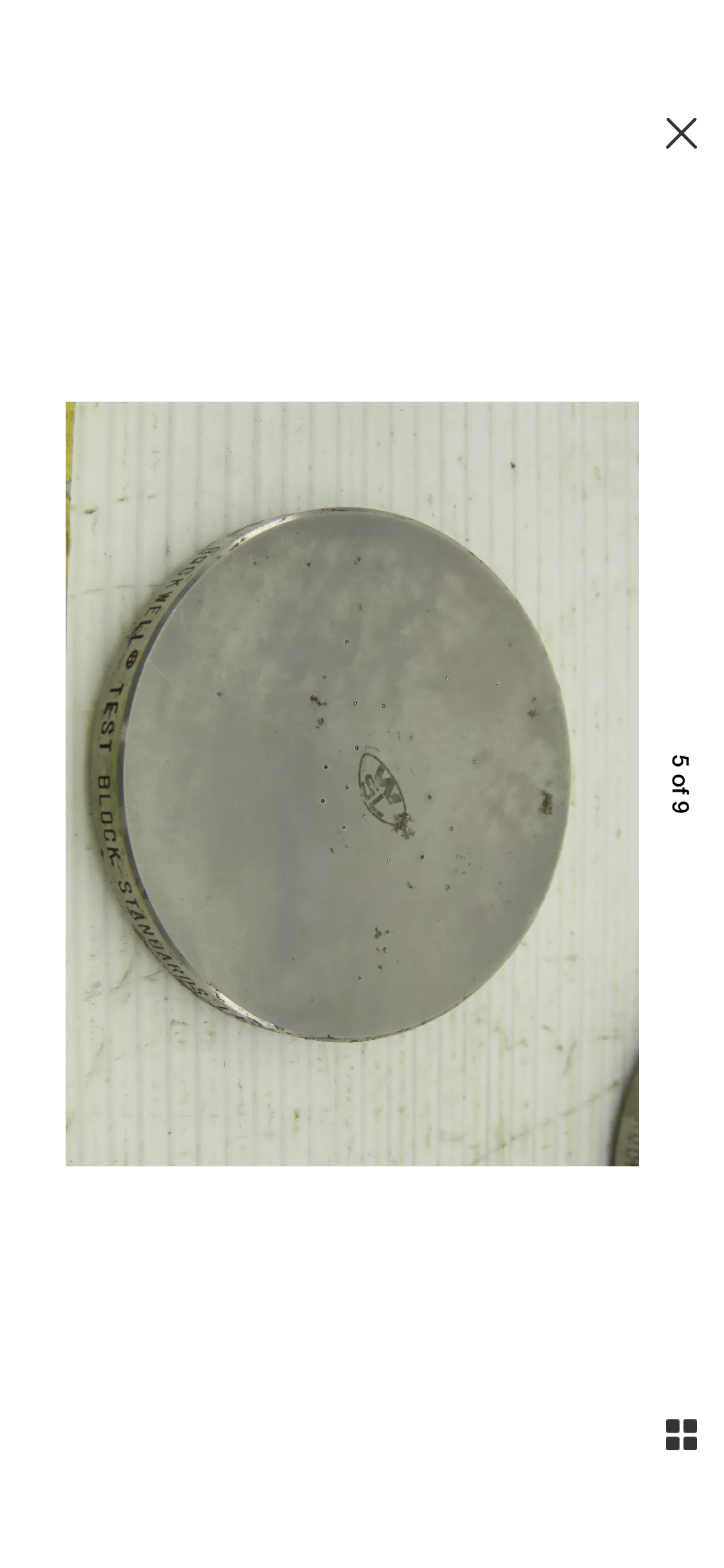

I’m looking for a test block/calibration block for a recently acquired Wilson Rockwell hardness tester. So over to “ebay” I go. Some are listed as A scale, some B, C ...... the list goes on. Some however are 11, 16, 88. This is where I get lost. I have looked online and there doesn’t seem to be any guidance. If someone wouldn’t mind taking the time I’d appreciate it.

Cheers,

Derek

Sent from my iPhone using Tapatalk

I’m looking for a test block/calibration block for a recently acquired Wilson Rockwell hardness tester. So over to “ebay” I go. Some are listed as A scale, some B, C ...... the list goes on. Some however are 11, 16, 88. This is where I get lost. I have looked online and there doesn’t seem to be any guidance. If someone wouldn’t mind taking the time I’d appreciate it.

Cheers,

Derek

Sent from my iPhone using Tapatalk