- Joined

- Jan 9, 2016

- Messages

- 120

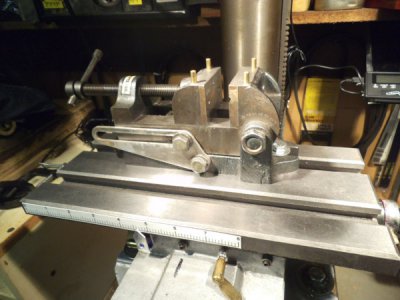

Tiring of the clamp, nudge, re-clamp, nudge it some more drill press setup game, I bought a Phase II cross-slide table. (A review of the same table by another forum member: http://www.hobby-machinist.com/threads/phase-ii-mil-drill-compound-cross-slide-review.15972/)

Not having a mill or any real experience with work holding on a flat table, I have no idea what hardware or additional accessories I need to cover setup and basic clamping.

Any recommendations? My best guess is something like this clamping kit from LMS. Would this be over the top, not enough, or ???

(I know this is a vague question, but I have NO idea what I'm doing here and don't want to buy stuff I'll never use, is complete junk, etc.)

Thanks!

Not having a mill or any real experience with work holding on a flat table, I have no idea what hardware or additional accessories I need to cover setup and basic clamping.

Any recommendations? My best guess is something like this clamping kit from LMS. Would this be over the top, not enough, or ???

(I know this is a vague question, but I have NO idea what I'm doing here and don't want to buy stuff I'll never use, is complete junk, etc.)

Thanks!