- Joined

- Oct 31, 2016

- Messages

- 2,643

I have been slowly resurrecting a 1966 MG Midget.

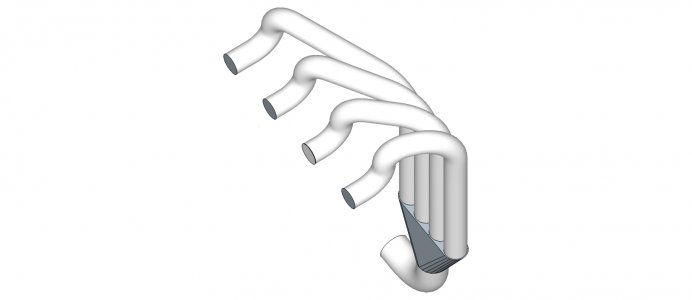

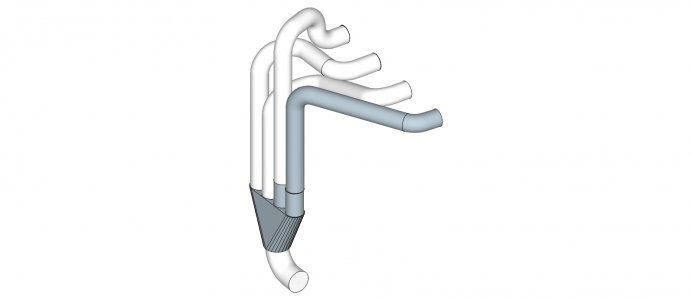

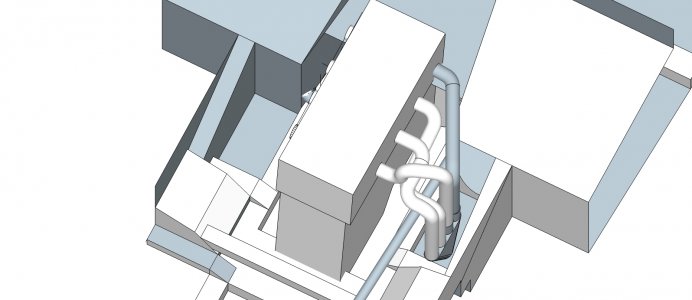

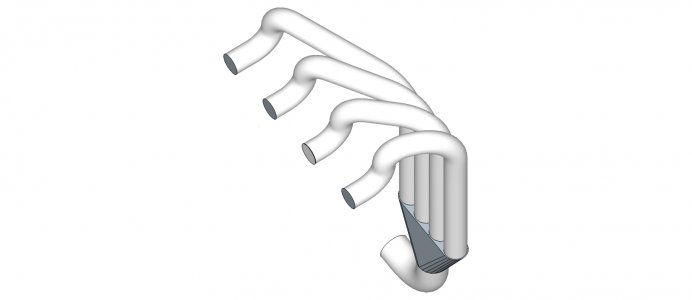

The original engine made less than 50 hp on a good day and the one in my car was frozen solid. In stead of paying thousands of dollars to have it rebuilt I am swapping a running Toyota 3 TC out of a 1982 Corrola into the midget. Current project among too many to count is headers. Others who have done this swap have ran the tubes over and under the steering column. If you have to remove the headers you have to take out the steering column. Every one who did this forgot about R&Ring the starter only to discover after the fact that they couldn't get the starter out without removing the headers. To avoid this you have to snake the tubes over the steering column and then down through a 3" x 7" slot between the steering column and two frame rails. Further complication is that from the edge of the exhaust port to the center of this slot is only 6". I did some mock ups with pvc pipe and thought I had it figured out. As a cross check I took really accurate measurements and did some 3d models in sketchup. What I thought would work was not even close. After countless hours on the computer I finally have a design that will work. I hope. Next I need to finish the exhaust flange and order the tubing and collector. Here's my latest and hopefully final design.

The original engine made less than 50 hp on a good day and the one in my car was frozen solid. In stead of paying thousands of dollars to have it rebuilt I am swapping a running Toyota 3 TC out of a 1982 Corrola into the midget. Current project among too many to count is headers. Others who have done this swap have ran the tubes over and under the steering column. If you have to remove the headers you have to take out the steering column. Every one who did this forgot about R&Ring the starter only to discover after the fact that they couldn't get the starter out without removing the headers. To avoid this you have to snake the tubes over the steering column and then down through a 3" x 7" slot between the steering column and two frame rails. Further complication is that from the edge of the exhaust port to the center of this slot is only 6". I did some mock ups with pvc pipe and thought I had it figured out. As a cross check I took really accurate measurements and did some 3d models in sketchup. What I thought would work was not even close. After countless hours on the computer I finally have a design that will work. I hope. Next I need to finish the exhaust flange and order the tubing and collector. Here's my latest and hopefully final design.