Guys updating all me post on all my Colchester issues so I though I would start another so that we can focus on headstock alignment.This needs to be done cause I completely took the headstock apart and to get the bed done.There are 4 bolts that hold the head down on the bed which are hard to get to with an allen wrench.Then on the end of the head stock I will need to remove the swing arm and what ever else to get to the adjustment screws.This I feel is going to be very tedious,and difficult to do.So I will need to read the manual several times,ask for some guidance along the way.Wanting get this done before summer cause its hard to do with sweat in my eyes,just plain hot in my little shop during the summer.Any youtubes,websites,articles????Getting very close,thanks guys---------------kroll

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Headstock Alignment On Colchester

- Thread starter Kroll

- Start date

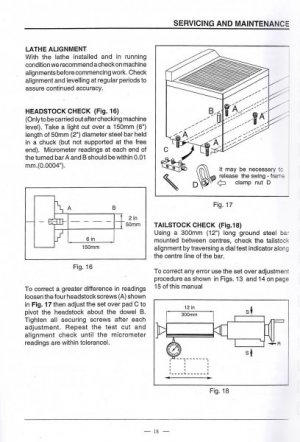

From my Clausing / Colchester 8000 series manual

Headstock alignments . insert 2" diameter steel bar in chuck. Do not support.

2. Take roughing cut. take light finishing cut over the 6" length.

3. Micrometer readings taken both ends.

4. Lathe power off, idler gear, swing frame clamp nut off.

5.Slacken 4 headstock securing screws.

6. Adjust the set over pad to pivot headstock. Small adjustments only are necessary . On your test piece if point A is chuck side, and point B is tail stock side then. As a guide ,with a dial indicator set against point B of the test piece it will be necessary to swing the headstock approximately 2 1/2 times the difference in micrometer readings between point A and point B ( Take your readings at both ends of your test piece. Use point B for your adjustment gauge. )

7. Tighten the headstock securing screws swing frame, refit idler gear repeat and test cut . REPEAT AND REPEAT AND REPEAT.

Good Luck hope it helps

Frank

Headstock alignments . insert 2" diameter steel bar in chuck. Do not support.

2. Take roughing cut. take light finishing cut over the 6" length.

3. Micrometer readings taken both ends.

4. Lathe power off, idler gear, swing frame clamp nut off.

5.Slacken 4 headstock securing screws.

6. Adjust the set over pad to pivot headstock. Small adjustments only are necessary . On your test piece if point A is chuck side, and point B is tail stock side then. As a guide ,with a dial indicator set against point B of the test piece it will be necessary to swing the headstock approximately 2 1/2 times the difference in micrometer readings between point A and point B ( Take your readings at both ends of your test piece. Use point B for your adjustment gauge. )

7. Tighten the headstock securing screws swing frame, refit idler gear repeat and test cut . REPEAT AND REPEAT AND REPEAT.

Good Luck hope it helps

Frank

Thank you Frank,I was wondering how to go about lining it up.Going to print this up and put it with the lathe,but I am going to wait till it cools off alittle so that I won't sweat all over the lathe.Yes sir this info is a big help,looking forward to my first project on my new to me lathe-----kroll

Dang here it is nice and cool this weekend so I start reading Franks post on how to do the alignment see I need a piece of bar stock.Well it wont be this weekend so I'll place a small order and wait alittle longer.Guys getting excited about this and reading the all the new post here in this section

- Joined

- Nov 18, 2013

- Messages

- 86

.From the uk lathe site

On Student and Master lathes the headstock pivots on a dowel, fitted to the back corner nearer the tailstock and can, as a consequence, be adjusted. At the left-hand end of the headstock, sitting between the bedways is a block with pointed-end Allen screws that can be used, by slackening one and tightening the other, to swing the headstock slightly. Before doing this the holding down bolts, which have a little clearance round their holes, should be slackened but not loosened completely. An accurate test bar will needed (it fits directly into the headstock spindle), together with a high-quality DTI used to assess the alignment. Alternatively, test cuts can be taken between minute amounts of adjustment with the holding-down bolts fully tightened, of course.

On Student and Master lathes the headstock pivots on a dowel, fitted to the back corner nearer the tailstock and can, as a consequence, be adjusted. At the left-hand end of the headstock, sitting between the bedways is a block with pointed-end Allen screws that can be used, by slackening one and tightening the other, to swing the headstock slightly. Before doing this the holding down bolts, which have a little clearance round their holes, should be slackened but not loosened completely. An accurate test bar will needed (it fits directly into the headstock spindle), together with a high-quality DTI used to assess the alignment. Alternatively, test cuts can be taken between minute amounts of adjustment with the holding-down bolts fully tightened, of course.

Thanks kiwi,I do remember the block and adjustment screws.But I was wondering how to handle the 4 bolts that holds down the headstock which are not easy to get to,but now I know thank you for passing on that information.I'm just afew days away from starting back on my lathe and want to get the headstock aligned.

- Joined

- Dec 29, 2013

- Messages

- 631

I am getting to do the same on My 8000 series Colchester. The adjustments do not seem to help at all. Where ever I move the headstock to, the mismeasurement seems to follow. I cannot seem to make it better, just move it around. Suspect a bearing problem, end play is taken up with more threads left, spindle doe not tighten up any more. Bearing never gets warm, I can push the same piece of steel .001-.002 with My bare hand. No way should I be able to do that, not a gorilla.