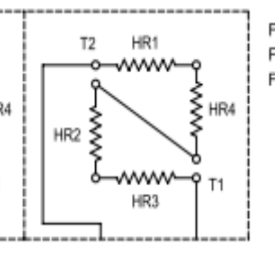

The element you have pictured looks to be the type that has the elements running inside along the raised ribbed sections from end to end length wise and turn back to the next rib along the short sides. In other words i would say that there are 6 runs of elements within that 1 rectangular block and i would venture a bet that you could cut into the element along the short side on either end and if you did so either directly to the left of the right side "leg" or better yet on the opposite side of the element directly opposite of the right side leg (on the other side of the brunt spot) you will be able to reconnect the right side leg and get you back in business.