- Joined

- Jun 22, 2012

- Messages

- 1,552

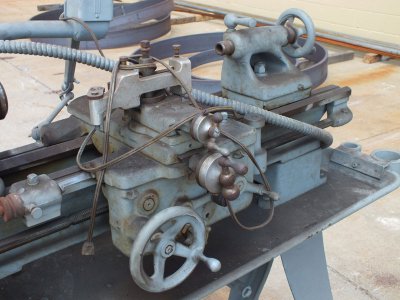

This is my first post other than an introduction. I have been searching for a used lathe to use for my tool making and who knows what else. I was hoping to find a nice workable logan and was looking for a few months. I work as a truck driver for a roll forming co. in the detroit area, one day on one of my deliveries to a shop that I go to all the time I was told to go upstairs to talk with the owner. Now this is a very old building in the heart of detroit, when I was up there I saw this old lathe tucked away in a corner surrounded by a ton of old machinery and other junk. So I asked, do you want to sell that lathe? He said I dunno, it's not mine, I have been storing it for a friend that lives out of state but i'll call him and see. A week later he said I called him and he will sell it, it was his fathers and he passed away and has no use for it, how much I said? He wants at least $500 for it. Can I look at it closer? I didn,t even know what brand it was as I couldn't get close to it, sure he said. As I aproached it I saw the large spindle bore, climbed around to the front of the lathe and saw it was a south bend! Oh happy day! Ways not damaged and in good shape, tail stock is there and functions smoothly, missing belt cover and bull gear cover is broken, handle for back gear eccentric is broken, But other than that it's all there and in good shape! original 3/4 hp 3 phase motor too. everything moves except the back gear and I think I can free it up. $500?.....I'll take it! Do you guys think this was a good deal? I will post pics as I go along with the refurb on this. Another question that I have is it looks like it has a collet chuck? Can I just remove the collet chuck and mount a 3 and 4 jaw chuck to this spindle or do I have to change the spindle shaft?

This is my first post other than an introduction. I have been searching for a used lathe to use for my tool making and who knows what else. I was hoping to find a nice workable logan and was looking for a few months. I work as a truck driver for a roll forming co. in the detroit area, one day on one of my deliveries to a shop that I go to all the time I was told to go upstairs to talk with the owner. Now this is a very old building in the heart of detroit, when I was up there I saw this old lathe tucked away in a corner surrounded by a ton of old machinery and other junk. So I asked, do you want to sell that lathe? He said I dunno, it's not mine, I have been storing it for a friend that lives out of state but i'll call him and see. A week later he said I called him and he will sell it, it was his fathers and he passed away and has no use for it, how much I said? He wants at least $500 for it. Can I look at it closer? I didn,t even know what brand it was as I couldn't get close to it, sure he said. As I aproached it I saw the large spindle bore, climbed around to the front of the lathe and saw it was a south bend! Oh happy day! Ways not damaged and in good shape, tail stock is there and functions smoothly, missing belt cover and bull gear cover is broken, handle for back gear eccentric is broken, But other than that it's all there and in good shape! original 3/4 hp 3 phase motor too. everything moves except the back gear and I think I can free it up. $500?.....I'll take it! Do you guys think this was a good deal? I will post pics as I go along with the refurb on this. Another question that I have is it looks like it has a collet chuck? Can I just remove the collet chuck and mount a 3 and 4 jaw chuck to this spindle or do I have to change the spindle shaft?

Last edited: