-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Heavy 10 project

- Thread starter woodtickgreg

- Start date

- Joined

- Jun 21, 2012

- Messages

- 193

Those ways look great....what did you use?

- Joined

- Jun 22, 2012

- Messages

- 1,552

The ways and everything else were either covered in gray primer or a coating of oil and crud. To remove the paint I scraped them with a new razor blade first then wiped them down with acetone. final clean up was with some 600 grit sand paper, didn't take much and they cleaned right up. They showed almost no wear, no grooves. No sign that the ways were ever scraped, not even under the headstock. Some people may not agree with using sand paper on the ways, but I assure you it was very light just to remove very light surface rust and gunk mostly. The razor blade and acetone removed 90% of the gunk. There was little if any metal removal in the clean up.Those ways look great....what did you use?

- Joined

- Jun 21, 2012

- Messages

- 193

Good to know. Yeah, some people would cringe at that...copper chore boys and brass brushes are good too, but i guess for that " one time" cleanup a very fine grit sandpaper is okay, as long as you clean the grit off very well. Otherwise its like lapping compound once mixed with oil. Still, it looks nice...and probably pretty darn accurate for hobby work, I dont care what anyone says.

- Joined

- Jun 22, 2012

- Messages

- 1,552

I look at it like this, how many people find a piece of machinery of this age with absolutely pristine ways? I would venture to say very few. Almost any machine of this age is going to need some clean up of the ways, no matter what you clean it with to remove any rust, and their will be some, you are going to have to use an abrasive something. even brass brushes or copper pads will remove some metal with the rust and grunge. My ways although needing a good cleaning are very sharp edged and angular, no wear grooves where the saddle rides. Look at the pics when I started this thread, I took a close up pic of the ways and they were not bad. I belive that cleaning them the way I did was the way (excuse the pun) to go. Lets say your lathe was very rusty, would you give up on it? I wouldn't, I would do the best I could, maybe as far as having everything reground or scrapped. I am sure there are lathes out there in far worse condition than mine being used in shops daily for production work. Sometimes I think people put to much into having a perfect machine. I have even consulted with a machinery rebuilder on this very same topic, the old south bends will hold a tolerance even with some significant wear, which mine does not have. Even though I intend to use this lathe, like all my tools, I want it to look good. I don't like using crummy dirty tools. Anybody that thinks that a 60+ year old lathe isn't going to have some wear of the ways is kidding themselves. jmoGood to know. Yeah, some people would cringe at that...copper chore boys and brass brushes are good too, but i guess for that " one time" cleanup a very fine grit sandpaper is okay, as long as you clean the grit off very well. Otherwise its like lapping compound once mixed with oil. Still, it looks nice...and probably pretty darn accurate for hobby work, I dont care what anyone says.

- Joined

- Jun 21, 2012

- Messages

- 193

I hear ya. I can't stand a messy workplace....disorganization gets in the way of efficient progress. Obviously, when you're using a tool, you're gonna make a mess. But, once chips or sawdust or whatever piles up, you take a quick break and clear the debris. At the end of the job, wipe down your lathe, table saw, or whatever tool you're using.

I do the same thing in the kitchen....it's called cleaning as you go, and it really reduces cleanup at the end....like to zero.

I've gotten into the habit of cleaning up at the end of each day I do something in the garage...even if the project is still in progress. When I come back to it, I can think clearly because I don't have a pile of tools and debris to contend with. Plus, I just like to look at a clean and well cared for machine. It's like a car; somehow it just drives better when it's clean

I do the same thing in the kitchen....it's called cleaning as you go, and it really reduces cleanup at the end....like to zero.

I've gotten into the habit of cleaning up at the end of each day I do something in the garage...even if the project is still in progress. When I come back to it, I can think clearly because I don't have a pile of tools and debris to contend with. Plus, I just like to look at a clean and well cared for machine. It's like a car; somehow it just drives better when it's clean

- Joined

- Jun 22, 2012

- Messages

- 1,552

I never said my shop was clean! LOL I just don't like crummy tools. I am a wood worker also, when I get involved in a project the shop gets trashed and not cleaned until the project is done. It's like that with the lathe restore right now and several other projects going on at the same time. The only thing I do during a project is an occasional sweep. I should be better at the cleaning thing, I guess I would rather work than clean.I hear ya. I can't stand a messy workplace....disorganization gets in the way of efficient progress. Obviously, when you're using a tool, you're gonna make a mess. But, once chips or sawdust or whatever piles up, you take a quick break and clear the debris. At the end of the job, wipe down your lathe, table saw, or whatever tool you're using.

I do the same thing in the kitchen....it's called cleaning as you go, and it really reduces cleanup at the end....like to zero.

I've gotten into the habit of cleaning up at the end of each day I do something in the garage...even if the project is still in progress. When I come back to it, I can think clearly because I don't have a pile of tools and debris to contend with. Plus, I just like to look at a clean and well cared for machine. It's like a car; somehow it just drives better when it's clean

- Joined

- Jun 21, 2012

- Messages

- 193

I guess there's something to be said for balance. I see some guys' shops and frankly it looks downright dangerous....especially when there's stuff you have to step over/around. OTOH, I see some of these shops that are so clean they're probably better than some operating rooms. I won't lie, I recently built some decent sized shop tables, but before that I did everything standing up or on the floor. On a project like yours, I'd have half a lathe laid out on cardboard to strip and paint and it definitly looked crazy to the neighbors.

- Joined

- Jun 22, 2012

- Messages

- 1,552

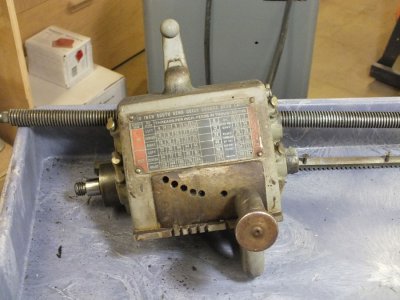

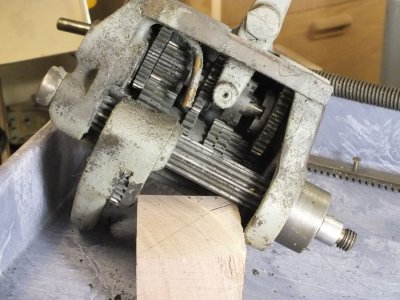

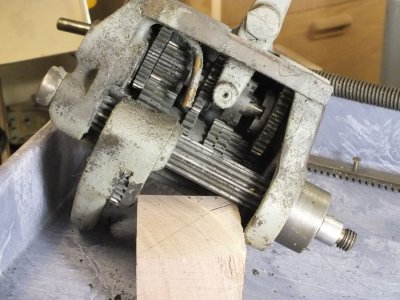

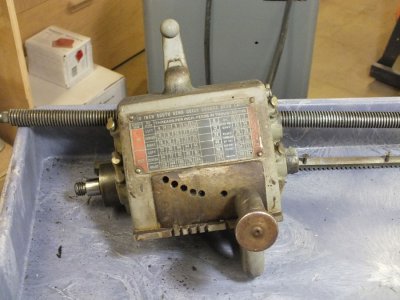

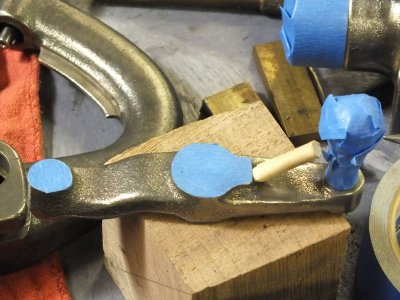

The doc says to work in my shop a little to help with my therapy. I can't argue with that! So yesterday I got the drive pullys and under drive pullys in the pedestal cleaned up and the new belt for the motor drive installed and adjusted. Today I started on the gear box tear down. I was very patient with it and even made a special punch out of an old plastic injection mold ejector pin, they are very hard and don't bend. Here's a few pics of the before. Next will be a trip to the parts washer and strip the housing in preparation for paint. everything came apart with little fuss, some extra work with the pins was all, nothing damaged in the dissassembly.

The doc says to work in my shop a little to help with my therapy. I can't argue with that! So yesterday I got the drive pullys and under drive pullys in the pedestal cleaned up and the new belt for the motor drive installed and adjusted. Today I started on the gear box tear down. I was very patient with it and even made a special punch out of an old plastic injection mold ejector pin, they are very hard and don't bend. Here's a few pics of the before. Next will be a trip to the parts washer and strip the housing in preparation for paint. everything came apart with little fuss, some extra work with the pins was all, nothing damaged in the dissassembly.

Last edited:

- Joined

- Jun 22, 2012

- Messages

- 1,552

A couple days ago I finally got some time to work on cleaning and inspecting the gear box. Let everything soak in the parts washer overnight and then brushed everything clean. I just use mineral spirits in my parts washer. Stripped all the paint off the castings and wire wheeled. All the gears looked real good and no scoring on the shafts. cleaned all the oil holes with pipe cleaners and removed the old rock hard and dirty wicks. I got everything all masked off and ready for paint too. The little wood pegs are to keep paint out of the oil holes. The reason they are not painted yet is because I was running all over town trying to find the paint I have been spraying in a quart can as I want to brush the gear box casting so I don't get over spray in the holes. I couldn't find it so I settled for a little darker gray color rust oleum, I guess I'm gonna have a 2 tone paint job now. LOL Should still look good I think, especiall if I do the apron, saddle, tail stock, and head stock the same color.

A couple days ago I finally got some time to work on cleaning and inspecting the gear box. Let everything soak in the parts washer overnight and then brushed everything clean. I just use mineral spirits in my parts washer. Stripped all the paint off the castings and wire wheeled. All the gears looked real good and no scoring on the shafts. cleaned all the oil holes with pipe cleaners and removed the old rock hard and dirty wicks. I got everything all masked off and ready for paint too. The little wood pegs are to keep paint out of the oil holes. The reason they are not painted yet is because I was running all over town trying to find the paint I have been spraying in a quart can as I want to brush the gear box casting so I don't get over spray in the holes. I couldn't find it so I settled for a little darker gray color rust oleum, I guess I'm gonna have a 2 tone paint job now. LOL Should still look good I think, especiall if I do the apron, saddle, tail stock, and head stock the same color.

Last edited: