- Joined

- Jan 3, 2020

- Messages

- 11

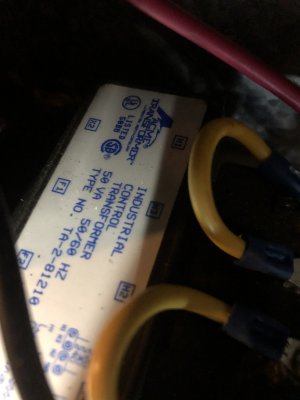

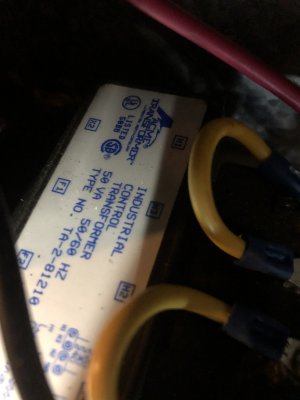

Just picked this up off Craigslist. Extremely interesting machine. For some reason, I couldn’t walk away from it...so it’s here! This isn’t my shop it’s an extra garage out front because I’m waiting on the ground to freeze to carry it around back to my shop. (Lots of mud here in Northern Ohio this year). Anywho, trying to figure out the wiring situation with it. It’s currently on a 1.5hp Baldor 3 phase motor. I’d like to be able to run it at 20amps if possible but I do have 220v. Attaching some photos on what’s on it currently and would love to hear any suggestions on what to do. I do have experience with VFD's, but this one already is variable speed by that little wheel above the number 57 beside the dovetails. My concern is, if I chose to convert via VFD, how would it impact the variable drive that's already on it? Hopefully from the wiring photos someone will be able to lead me in the right direction. If you need more pictures or information, I can get that for you as well. I'm really excited to get this thing back to my shop.

The other issue with it is the power feed isn't working, seems to be missing a couple parts and on the left side there's another handle (which I'm assuming is the brake for a collet or something, but it doesn't engage (not sure if i have to have a collet inside there for it to engage or not but they are on order). Overall, the mill works fantastic, I got to test it out before I bought it. It has high/low gearing using that knob on the top right sticking out there and a huge RPM range. The table is very smooth, not much slop maybe 12 thousands and 18 thousands on the handles.

The other issue with it is the power feed isn't working, seems to be missing a couple parts and on the left side there's another handle (which I'm assuming is the brake for a collet or something, but it doesn't engage (not sure if i have to have a collet inside there for it to engage or not but they are on order). Overall, the mill works fantastic, I got to test it out before I bought it. It has high/low gearing using that knob on the top right sticking out there and a huge RPM range. The table is very smooth, not much slop maybe 12 thousands and 18 thousands on the handles.

Attachments

Last edited: