Hello all, new guy looking for some help.

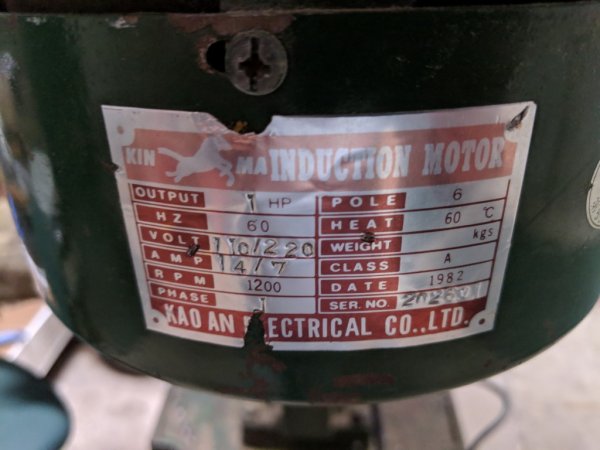

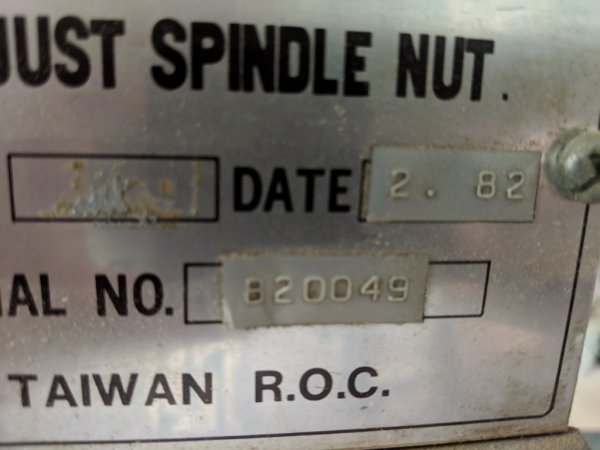

The school I teach at is getting a new CNC Haas for the FabLab, so I'm able to pick up the pictured Enco mill for $100-200. This will hopefully be followed closely by the old south bend lathe! I'm hoping you all might be able to help me ID it. The date tag and motor say 1982, but the model number is rubbed off. It's a 1hp, dual voltage round column Taiwan mill. This would be for light repair or fab work and gunsmithing. Any idea the collet on these and are there manuals or tutorials out there?

After several hours of Googling I've found about a billion people that say they aren't worth the space they take up or hassle of moving, and then guys who actually use them they work fine.

The school I teach at is getting a new CNC Haas for the FabLab, so I'm able to pick up the pictured Enco mill for $100-200. This will hopefully be followed closely by the old south bend lathe! I'm hoping you all might be able to help me ID it. The date tag and motor say 1982, but the model number is rubbed off. It's a 1hp, dual voltage round column Taiwan mill. This would be for light repair or fab work and gunsmithing. Any idea the collet on these and are there manuals or tutorials out there?

After several hours of Googling I've found about a billion people that say they aren't worth the space they take up or hassle of moving, and then guys who actually use them they work fine.