- Joined

- Sep 7, 2019

- Messages

- 674

Hey all, I just recently joined the Atlas 7B club! I picked up the machine from a member a few weeks ago. I had to disassemble it somewhat to get it down my basement steps into my workshop. After getting it lifted up and re-mounted to the stand I want to ask you guys for some advice before I start using it. Mainly I'm wondering about lubrication.

I have a lubrication chart along with a reprint of the original manual but what I'd like to know is which fittings on my particular machine are factory and which have been added by previous owners. I'd like the machine to be as it was from Atlas all those years ago unless, in your guys' opinions, the changes are made for the better.

First a shot of the machine on it's table, I had to remove the motor and related bracketry to lighten the load. I used a full size sheet pan for an oil tray. Hopefully it catches most of the drippings. I've heard that these machines when properly lubed will leak oil a lot.

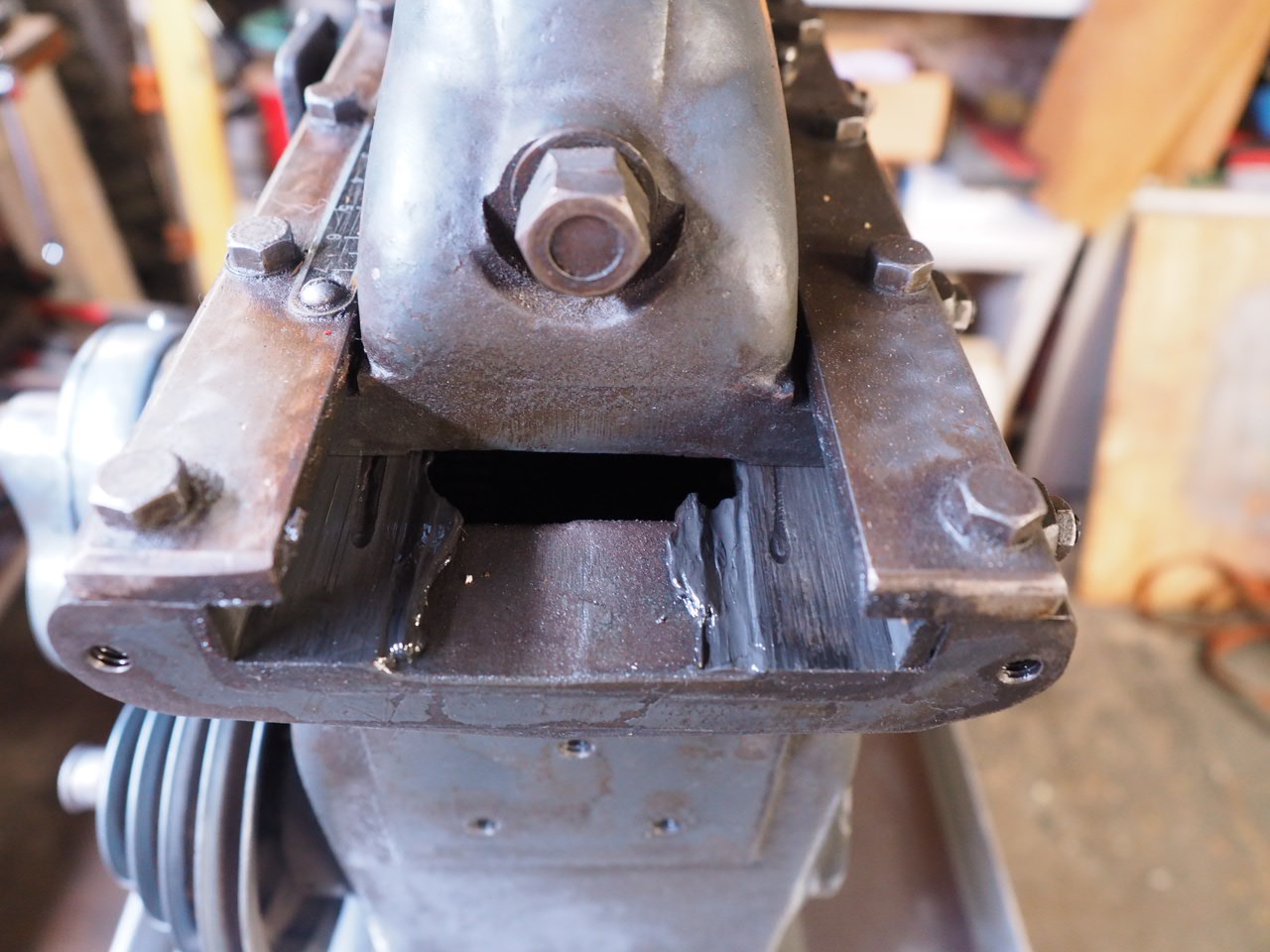

Now to the main issues. It looks like a previous owner had used grease on the ram. According to the manual this is incorrect. I'd like to rectify this before I begin using the machine.

On the left side of the ram is this grease fitting. I'm guessing it's not factory? The other side has just a small threaded hole. Are these meant to be oil cups?

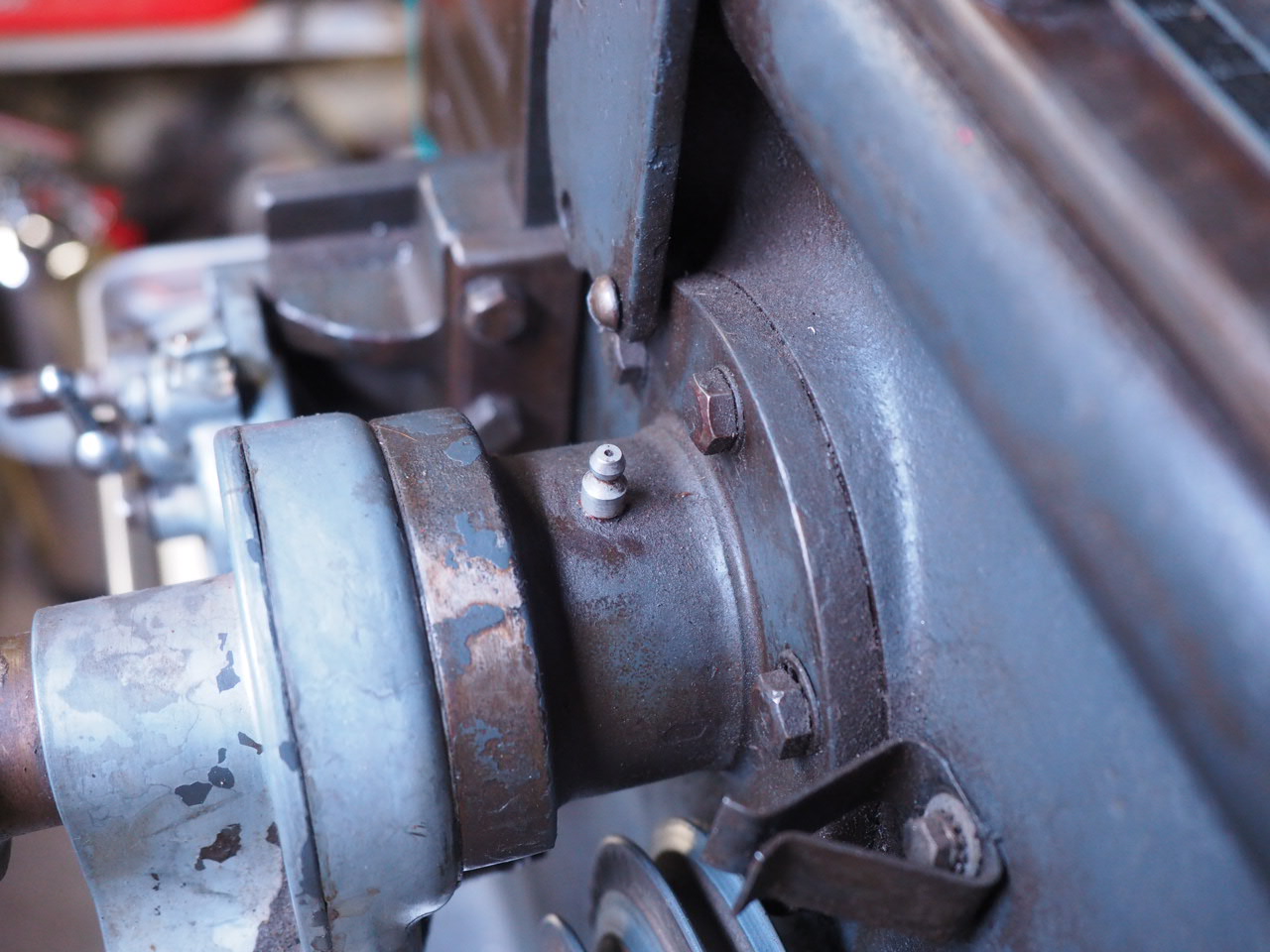

Here you can see a zerk fitting has been added on the inside of the grease cup on one of the shafts. The cup is still present, just removed for the picture. Am I correct that there should be no zerk here, only a hole for the grease cup to press the grease into the shaft?

Here's some more zerk fittings. Are these ones correct?

The oilers in the pic below look like factory fittings.

Finally there's this hole at the rear of the machine. Should it be plugged? It has threads.

Thanks in advance for any help and advice! There's a lot of knowledge on this forum, I hope I can glean something from it!

I have a lubrication chart along with a reprint of the original manual but what I'd like to know is which fittings on my particular machine are factory and which have been added by previous owners. I'd like the machine to be as it was from Atlas all those years ago unless, in your guys' opinions, the changes are made for the better.

First a shot of the machine on it's table, I had to remove the motor and related bracketry to lighten the load. I used a full size sheet pan for an oil tray. Hopefully it catches most of the drippings. I've heard that these machines when properly lubed will leak oil a lot.

Now to the main issues. It looks like a previous owner had used grease on the ram. According to the manual this is incorrect. I'd like to rectify this before I begin using the machine.

On the left side of the ram is this grease fitting. I'm guessing it's not factory? The other side has just a small threaded hole. Are these meant to be oil cups?

Here you can see a zerk fitting has been added on the inside of the grease cup on one of the shafts. The cup is still present, just removed for the picture. Am I correct that there should be no zerk here, only a hole for the grease cup to press the grease into the shaft?

Here's some more zerk fittings. Are these ones correct?

The oilers in the pic below look like factory fittings.

Finally there's this hole at the rear of the machine. Should it be plugged? It has threads.

Thanks in advance for any help and advice! There's a lot of knowledge on this forum, I hope I can glean something from it!