- Joined

- Mar 30, 2019

- Messages

- 171

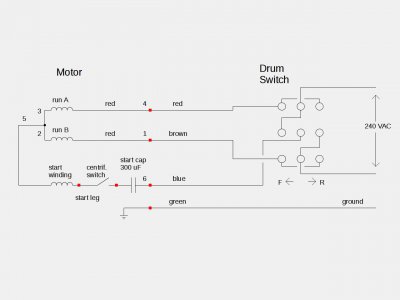

Those little red wires with blue insulators power a light, they grab power off 1 leg of the 220 circuit. That’s the ONLY thing I’m sure about on this set up! Lol yes the motor has five wires coming out of it and is supposed to connect to the reversing switch. But at this time they are just hanging down, not connectEd at all. That is were my problem lays, what wire to put where on the reversing switch. I will get more pictures, today. The reversing switch is kinda straight forward, as the center three terminals receive power, that is ground/neutral and the the two power legs on the bottom two terminals. The the top and next to the top of the center terminals are connected by what looks like a factory connecter. Then when you turn the switch one way, it connects all the center terminals to right side terminals. If you turn it the other way it connects to the left side terminals. One question I have is what are the littke factory wires that seem to connect the left side with the right side? Are they resister wires or diodes? I think I can see something in the diagrams that indicates they are something like that. Any help will be appreciated.

The way the motor is wired now , to me does follow, either diagram in the motor cover. I cannot prove that that junction box cover lid is original to the motor... it looks like it is. But it only shows four wires..... but six wires come out of the motor, into the box and five wires leave the box. But I do not know it that is right or necessary. I bought this mill this way, so I have no history as to why it is like this.

Bones

The way the motor is wired now , to me does follow, either diagram in the motor cover. I cannot prove that that junction box cover lid is original to the motor... it looks like it is. But it only shows four wires..... but six wires come out of the motor, into the box and five wires leave the box. But I do not know it that is right or necessary. I bought this mill this way, so I have no history as to why it is like this.

Bones

Last edited: