- Joined

- Nov 9, 2015

- Messages

- 406

I have taken the next step of modeling the box and gears, and based on input from you guys, have further developed a repair strategy. I am now working on the fixtures necessary to ensure alignment for the brazing process.

Here is the damaged box - front and rear (click to enlarge):

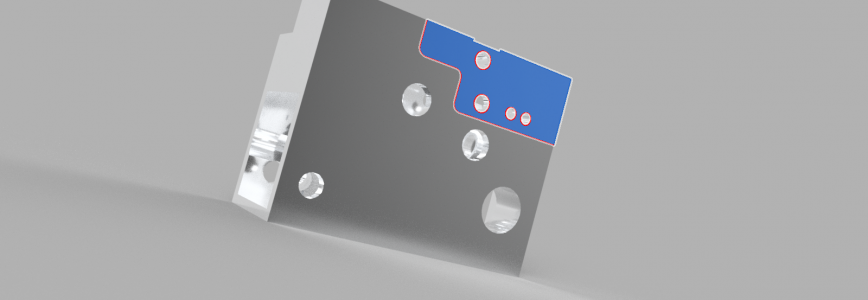

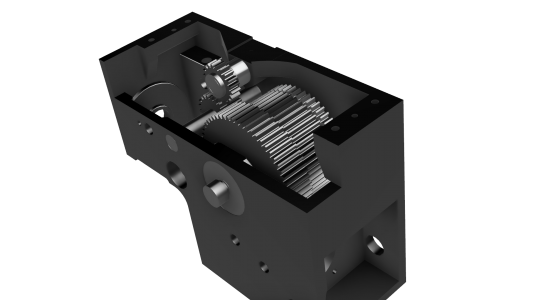

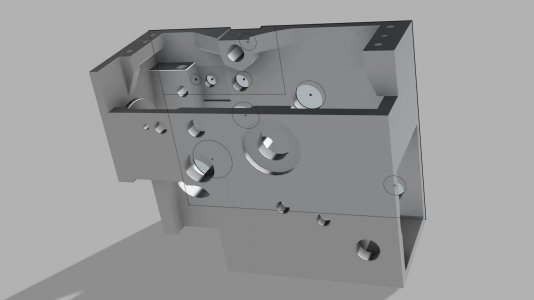

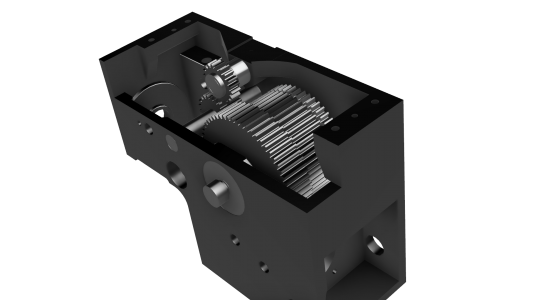

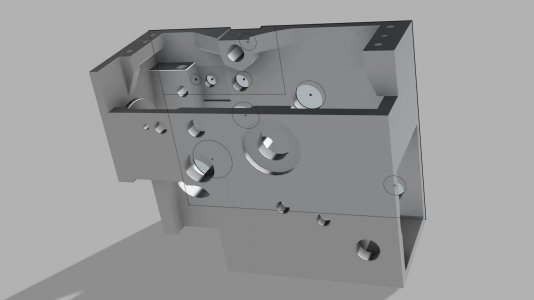

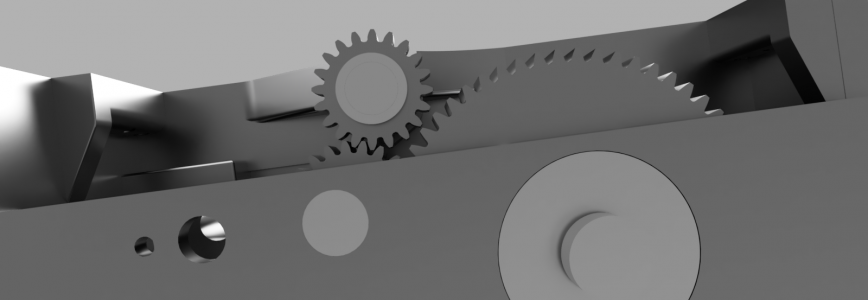

Here is the modeled box and affected gears. First a rendering of the entire model then a look from the back without the gears. You can (barely) see -- in the image on the right -- the cut-out lines for the replacement part in the upper left hand corner (click to enlarge).

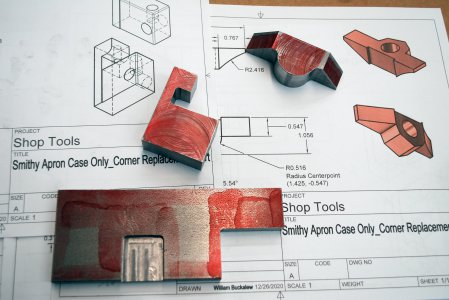

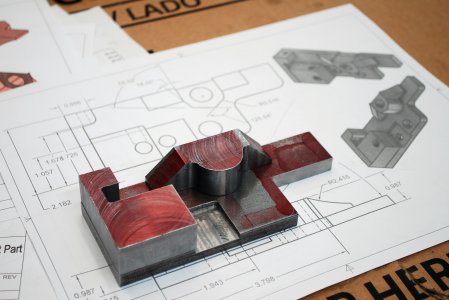

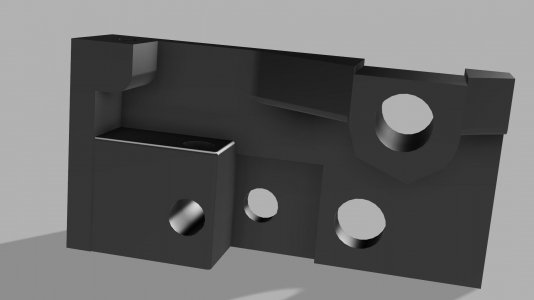

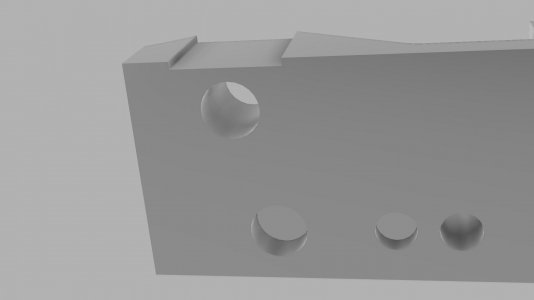

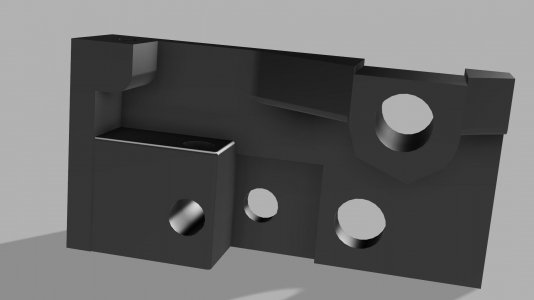

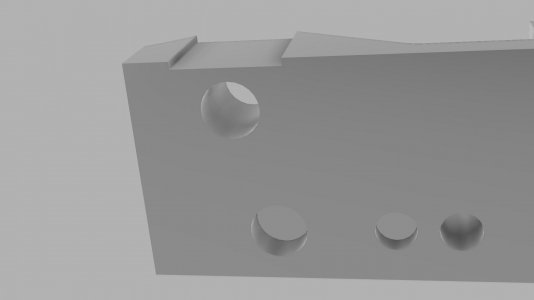

And a blow-up of the replacement part that will fit in the cut-out of the upper right hand corner of the box, rear and front. I am thinking the replacement part will be a plate of 1018 with a couple of 1018 blocks MIG welded to it, then milled to shape prior to brazing (click to enlarge).

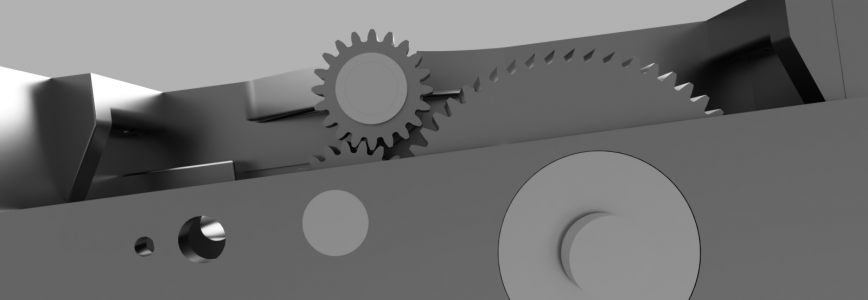

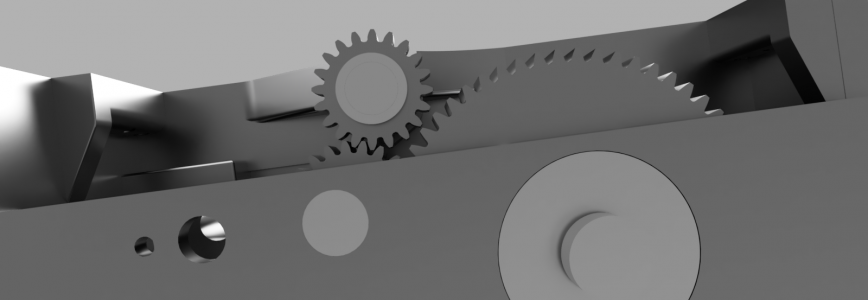

And finally a close-up of the model gear mesh. Looks like the model is pretty accurate.

Thanks again for all of the input. I would appreciate any additional thoughts!!

Here is the damaged box - front and rear (click to enlarge):

Here is the modeled box and affected gears. First a rendering of the entire model then a look from the back without the gears. You can (barely) see -- in the image on the right -- the cut-out lines for the replacement part in the upper left hand corner (click to enlarge).

And a blow-up of the replacement part that will fit in the cut-out of the upper right hand corner of the box, rear and front. I am thinking the replacement part will be a plate of 1018 with a couple of 1018 blocks MIG welded to it, then milled to shape prior to brazing (click to enlarge).

And finally a close-up of the model gear mesh. Looks like the model is pretty accurate.

Thanks again for all of the input. I would appreciate any additional thoughts!!

Attachments

Last edited: