-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

[How-To] Help Please. How would you repair this Cracked Cast Iron Lathe Apron (Off a Smithy Granite). Braze or Weld?

- Thread starter bill70j

- Start date

- Joined

- Apr 29, 2019

- Messages

- 2,055

And all those that said it could not be done........

Looks great, and now you have learned a new skill.

The real test will be taking a nice heavy cut and see if it all stays together. I could not tell from the pics if you had full penetration of the brazing.

Looks great, and now you have learned a new skill.

The real test will be taking a nice heavy cut and see if it all stays together. I could not tell from the pics if you had full penetration of the brazing.

- Joined

- Apr 23, 2018

- Messages

- 6,505

Clear coat that and call it done!

- Joined

- Sep 28, 2013

- Messages

- 4,300

that is seriously impressive work, well done!

- Joined

- Feb 2, 2013

- Messages

- 3,619

great job on the repair!

- Joined

- Nov 9, 2015

- Messages

- 406

Thanks to all for your input on this repair. Every comment has been quite helpful. I appreciate that!!

I am ready to to install the repaired assembly on the lathe. It will replace the brand new assembly that I installed after I crashed the machine. Then I'll try to sell the newer one.

But before I go selling the new apron assembly, I will make some side-by side comparisons to make sure the repaired unit will preform properly. This will include some static measurements followed by a test of the new assembly at 3000RPM making heavy cuts under power.

I'll report back on how it works - or how it doesn't.

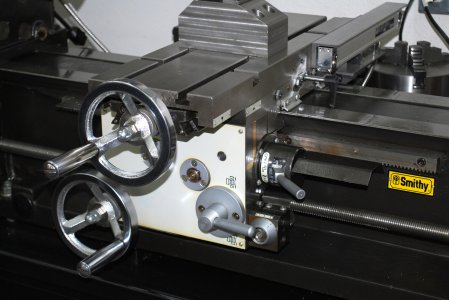

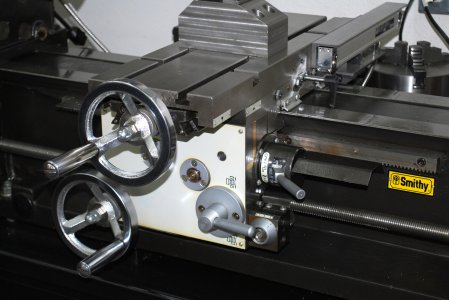

Here's a photo of the repaired unit, and the the one that it's going to replace. Out with the new and in with the old.

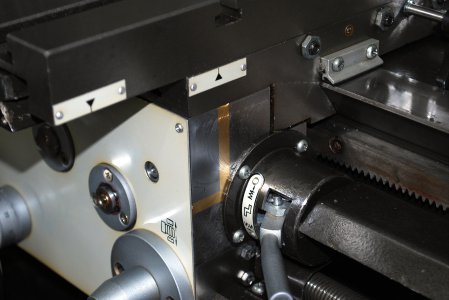

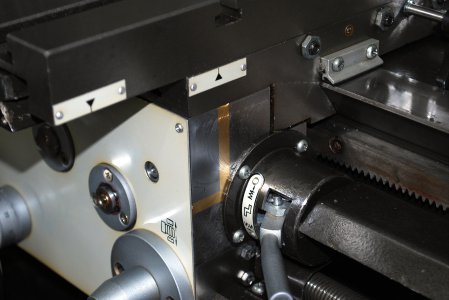

Next Day. Well, the repaired assembly has now been installed and tested. Works fine. Only evidence of repair is a small scar near the power feed lever. All done.

Weld cast iron, braze cast iron, cast iron repair, cast iron casting repair, crack in cast iron, cast iron repair oxyacetylene, gas brazing, gas welding brazing torch, brazing rod, flux,Smithy Granite apron

I am ready to to install the repaired assembly on the lathe. It will replace the brand new assembly that I installed after I crashed the machine. Then I'll try to sell the newer one.

But before I go selling the new apron assembly, I will make some side-by side comparisons to make sure the repaired unit will preform properly. This will include some static measurements followed by a test of the new assembly at 3000RPM making heavy cuts under power.

I'll report back on how it works - or how it doesn't.

Here's a photo of the repaired unit, and the the one that it's going to replace. Out with the new and in with the old.

Next Day. Well, the repaired assembly has now been installed and tested. Works fine. Only evidence of repair is a small scar near the power feed lever. All done.

Weld cast iron, braze cast iron, cast iron repair, cast iron casting repair, crack in cast iron, cast iron repair oxyacetylene, gas brazing, gas welding brazing torch, brazing rod, flux,Smithy Granite apron

Last edited: