- Joined

- Oct 31, 2016

- Messages

- 2,643

Hi,

I was using my HF 125 today and all of a sudden it stopped working. My original thought was that maybe it had over heated some how. I had done 4 tacks and then about an inch long bead. Power on max and wire feed on four.

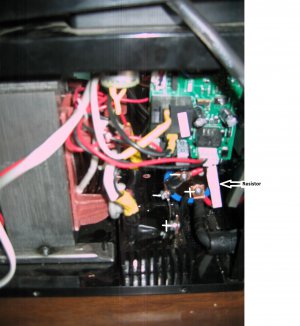

I have done the bridge rectifier/capacitor modification. The welder powers on. The fan runs. When I push the switch I hear a click and a buzzing sound. The wire does not feed. When I touch the wire to what I am welding there is a tiny spark.

Where do I start to trouble shoot what has gone wrong with my welder?

I was using my HF 125 today and all of a sudden it stopped working. My original thought was that maybe it had over heated some how. I had done 4 tacks and then about an inch long bead. Power on max and wire feed on four.

I have done the bridge rectifier/capacitor modification. The welder powers on. The fan runs. When I push the switch I hear a click and a buzzing sound. The wire does not feed. When I touch the wire to what I am welding there is a tiny spark.

Where do I start to trouble shoot what has gone wrong with my welder?