- Joined

- Aug 17, 2018

- Messages

- 57

Hello all!

first of thank you so much for taking the time to read this, I am a complete newby to machining.

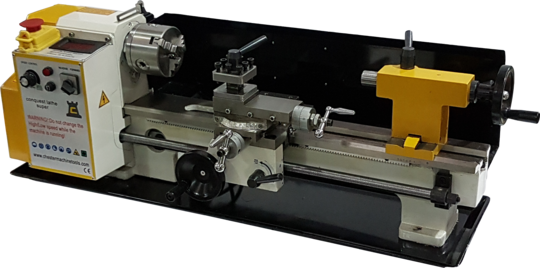

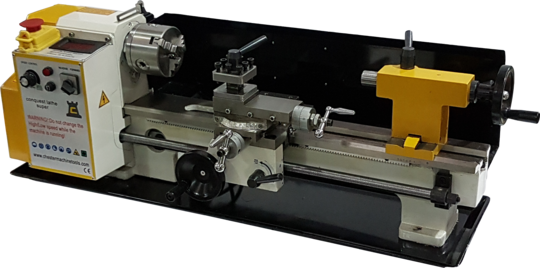

I've just purchased a second hand mini lathe:

"conquest super lathe" 7X14'' ,

for very cheap it comes with this set of carbine tools:

tungsten-carbide-lathe-tool-set-8mm-536001

This secondary chuck: axminster clubman sk100 woodturning chuck

ax915228

--------

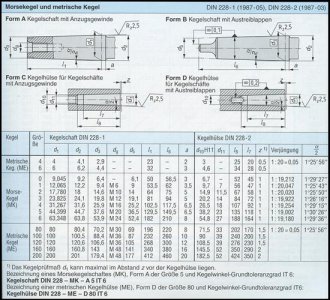

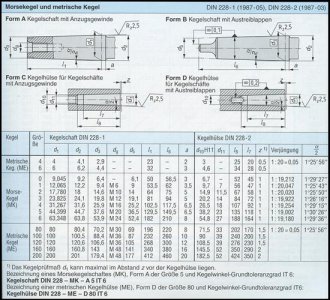

and this arbor: mt2-arbor-m33-x-3-5

Now to the crux of the matter the arbor needs to be turned to remove the wider part of the arbor just above the visible black thread. I need to remove quite a bit of the arbor to allow the arbor to nestle into the back of the chuck so the thread grips it into the chuck so I can then fit it to the lathe.

I have absolutly no idea if this can be done on the small conquest, or I need to send this peice off, or if I need to send the chuck of for a custom arbor to be made or if I can buy a arbor...

I really need some guidance, I'd love to use the arbor that the job lot is coming with but again:

I have no clue if this can be done on this lathe?

If it can what tool to use HSS/ Carbine/ Tugsten ?

Kind regards

Chris

first of thank you so much for taking the time to read this, I am a complete newby to machining.

I've just purchased a second hand mini lathe:

"conquest super lathe" 7X14'' ,

for very cheap it comes with this set of carbine tools:

tungsten-carbide-lathe-tool-set-8mm-536001

This secondary chuck: axminster clubman sk100 woodturning chuck

ax915228

--------

and this arbor: mt2-arbor-m33-x-3-5

Now to the crux of the matter the arbor needs to be turned to remove the wider part of the arbor just above the visible black thread. I need to remove quite a bit of the arbor to allow the arbor to nestle into the back of the chuck so the thread grips it into the chuck so I can then fit it to the lathe.

I have absolutly no idea if this can be done on the small conquest, or I need to send this peice off, or if I need to send the chuck of for a custom arbor to be made or if I can buy a arbor...

I really need some guidance, I'd love to use the arbor that the job lot is coming with but again:

I have no clue if this can be done on this lathe?

If it can what tool to use HSS/ Carbine/ Tugsten ?

Kind regards

Chris