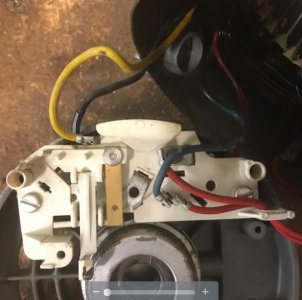

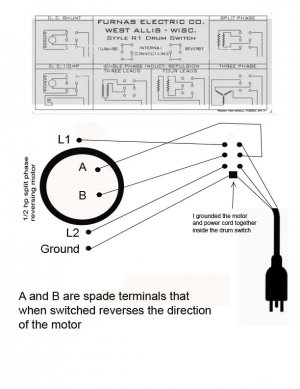

I need some advise on what is going on with my motor and drum switch. I have a 1/2 hp split phase reversing motor that I have wired to a Furnas drum switch on my little SB 9c. I have it wired as in the diagram and it will run forward and reverse as it is supposed to. However when it runs for a little bit the motor smells like it is getting hot and the case of the motor gets hot. I can disconnect the motor from the drum switch and connect power directly to the motor and it seems to run fine without getting hot. This obviously tells me something is going on with my wiring.

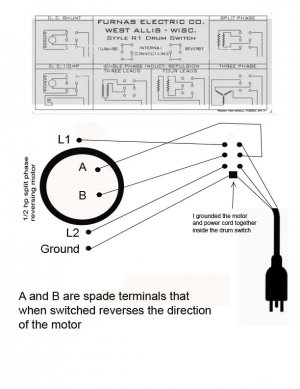

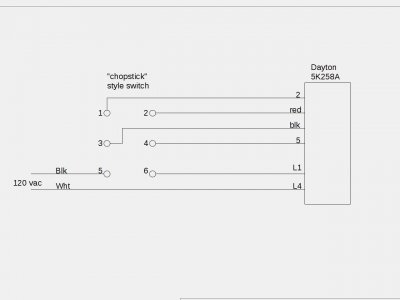

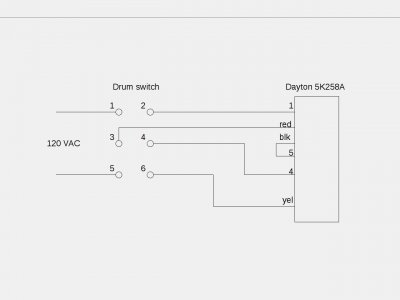

The motor has two spade terminals and indicates to reverse the direction of the motor to just switch the two spade terminals. I have attached a diagram of how I currently have it wired. I am trying to wire it as per the diagram in the upper right hand corner schematic. Any ideas would be greatly appreciated.

The motor has two spade terminals and indicates to reverse the direction of the motor to just switch the two spade terminals. I have attached a diagram of how I currently have it wired. I am trying to wire it as per the diagram in the upper right hand corner schematic. Any ideas would be greatly appreciated.