- Joined

- Sep 21, 2017

- Messages

- 96

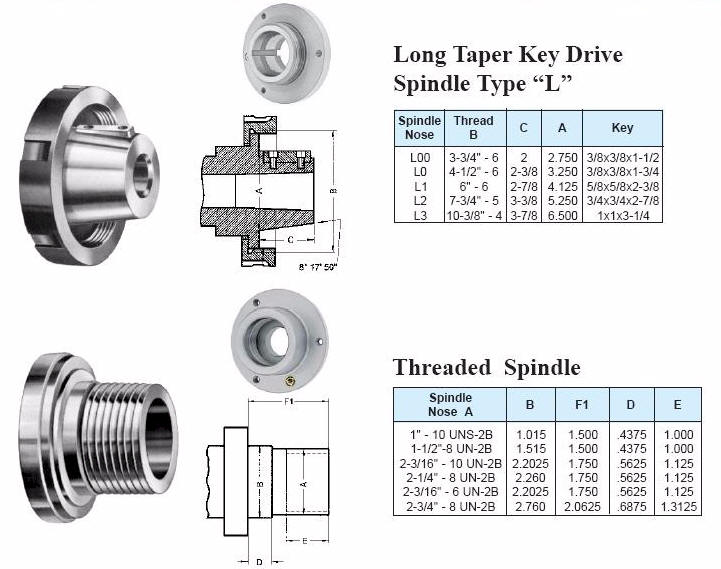

I have just acquired an Ellis dividing head in remarkably good and mostly complete condition. Photos show what I have. What I don't have, or think I don't have are collets and a center. At the sellers home I decided that it used 3C collets, which I use on my 9" South Bend. However on getting back to the shop, I am not sure. The 3C almost fits, but not all the way. I have not yet done a really good clean out on the spindle, but still not sure that will be sufficient. Does anyone have any knowledge about these? Is this some variation of 3C? I also have to check out the thread on the spindle to see if I can use a chuck from my lathe.

Information seems to be scarce for these dividing heads.

Sent from my SM-G930T using Tapatalk

Information seems to be scarce for these dividing heads.

Sent from my SM-G930T using Tapatalk