Hey guys,

So I’m trying to find a decent thread pitch gauge set, which I can use with in tandem with my digital calipers in order to identify the threads of most screws, bolts, and pipe threads that I come across; however, this has proven to be difficult.

I bought a set off of Amazon for $23 (see images 1 and 2), but it didn’t come with a reference guide or instructions of any kind, so I scoured the Internet looking for instruction and a proper reference guide, but I've come up a bit short.

Here is what I've learned:

My questions:

Is my set any good, if not, where can I find a good set for under $100?

How do you use those three single-piece gauges that look like a more arrow dynamic version of the USS Enterprise? Are they used to check gap angles between threads as well as something else?

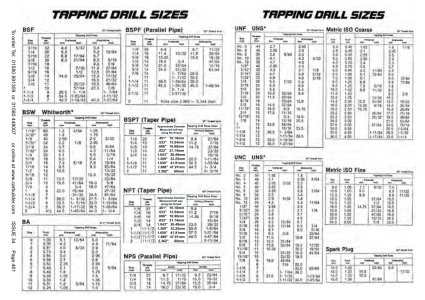

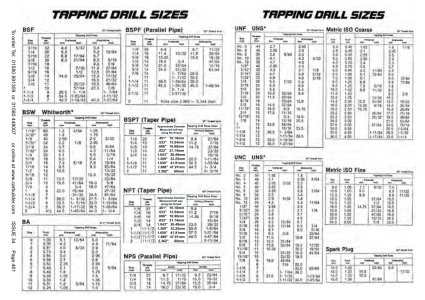

Where do I find a good reference manual and/or guide to use with my pitch gauges? I found a guide at CarBuilderSolutions.com (see 3rd image), however, it is pretty pixelated and doesn't seem complete.

My apologies for the length.

I'd appreciate any help that can be given.

Thank you,

-Jeff

So I’m trying to find a decent thread pitch gauge set, which I can use with in tandem with my digital calipers in order to identify the threads of most screws, bolts, and pipe threads that I come across; however, this has proven to be difficult.

I bought a set off of Amazon for $23 (see images 1 and 2), but it didn’t come with a reference guide or instructions of any kind, so I scoured the Internet looking for instruction and a proper reference guide, but I've come up a bit short.

Here is what I've learned:

The most common standards for Britain are Whitworth and BSF. American sizes are typically UNF and UNC. International sizes are typically Metric ISO Fine and Metric ISO Coarse. Whitworth, BSF, UNF, and UNC identify threads by threads per inch (TPI) and Metric uses the distance between two consecutive threads as the pitch. Apparently, there are both tapered and parallel threads for these systems.

My questions:

Is my set any good, if not, where can I find a good set for under $100?

How do you use those three single-piece gauges that look like a more arrow dynamic version of the USS Enterprise? Are they used to check gap angles between threads as well as something else?

Where do I find a good reference manual and/or guide to use with my pitch gauges? I found a guide at CarBuilderSolutions.com (see 3rd image), however, it is pretty pixelated and doesn't seem complete.

My apologies for the length.

I'd appreciate any help that can be given.

Thank you,

-Jeff