- Joined

- Jan 29, 2013

- Messages

- 176

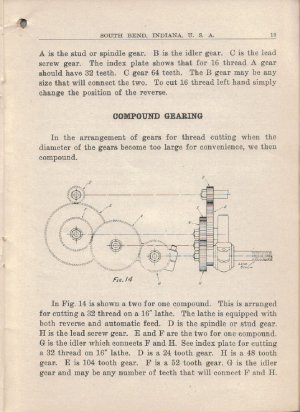

Guys, I need some help if yall can, Look at this picture and tell me if this is right or if I need to change something. When I got this lathe it had three pully's & a belt instead of gears, so I didn't have an example of how they are supposed to be, I've been looking on the web but not finding real clear pictures of what I need, I've got the book but having trouble figuring it out, I've tried several different searches but no luck, Here's a picture of the way I have it but with some arrows drawn in for a question, should the bushing pointed to with the red arrow be on the back side of this gear so it will run on the outer gear pointed to with the blue arrow rather than the inner one like it is now, hope I'm making myself clear, thanks for any help you have,

Dwayne

Dwayne