- Joined

- Mar 26, 2018

- Messages

- 2,724

Hi all,

I own an Enco 110-2033 (12x36 lathe similar to the G9249 from Grizzly). I was trying to cut a 1.125-18 thread this past weekend and couldn't figure out how to disengage and re-engage the halfnuts for this 18 TPI thread.

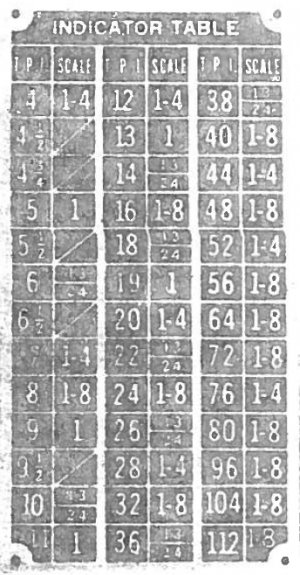

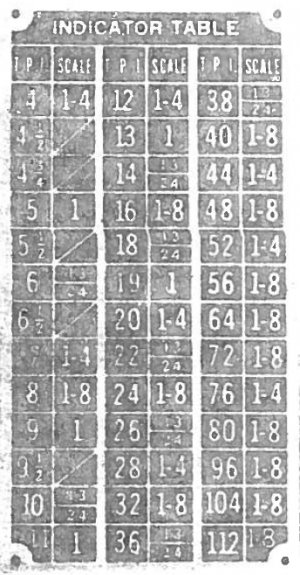

Here is the thread chart. My machine have a thread dial with 4 large ticks labeled 1,2,3, and 4 with shorter ticks in between each of the large marks.

If I started on the line marked "1" and then later re-engaged the thread on "1", the threads didn't line up. I ended up keeping the half nuts engaged the whole time and cutting the thread like I would a metric one. Any tips for what the 1/2 3/4 means on the 18 TPI entry in the table?

Thanks!

-Mike

I own an Enco 110-2033 (12x36 lathe similar to the G9249 from Grizzly). I was trying to cut a 1.125-18 thread this past weekend and couldn't figure out how to disengage and re-engage the halfnuts for this 18 TPI thread.

Here is the thread chart. My machine have a thread dial with 4 large ticks labeled 1,2,3, and 4 with shorter ticks in between each of the large marks.

If I started on the line marked "1" and then later re-engaged the thread on "1", the threads didn't line up. I ended up keeping the half nuts engaged the whole time and cutting the thread like I would a metric one. Any tips for what the 1/2 3/4 means on the 18 TPI entry in the table?

Thanks!

-Mike