- Joined

- Nov 29, 2017

- Messages

- 530

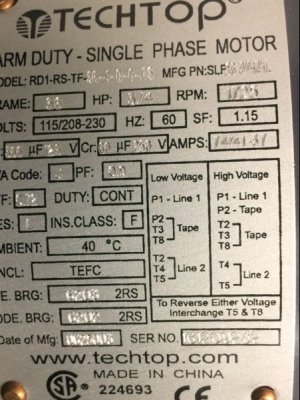

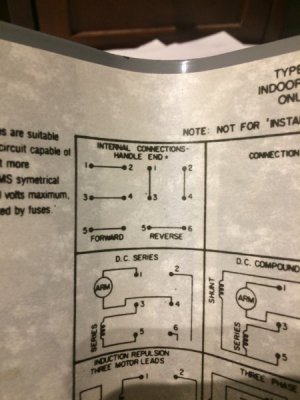

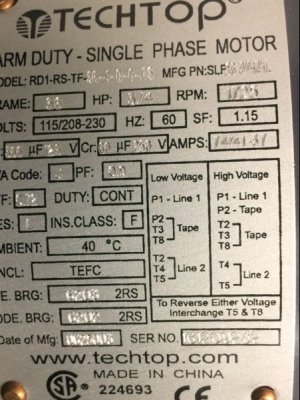

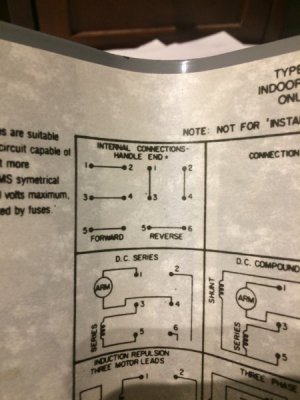

I’m trying to wire a 3/4 hp motor for 110 v to drum switch for my mill. I’ve searched and found several threads but can’t convince myself that my motor/switch combination is the same as discussed. I’m attaching pictures of my motor plate and switch. Any help greatly appreciated. I’m totally out of my element.