-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help with my Atlas Lathe

- Thread starter ZouchaR

- Start date

It starts right up... and without a load.. it runs just fine... but as soon as I put a load on it... doing a cut... it bogs down and stops... I haven't actually taken it all the way down to a stop because I don't want to damage the motor.. but it would stop if I allowed it...It would have to be the run side. Sounds like it’s starting fine.

Sent from my iPhone using Tapatalk

- Joined

- Jun 29, 2014

- Messages

- 4,059

If you have two capacitors on the motor, it could be that the run capacitor is shot. Since it starts fine, one could assume your start capacitor is fine. All of this assumes you have a two capacitor motor.

If that isn’t it, I’d swap the motor out and see if that makes the difference.

Have you tried cutting other materials on this machine? Are you able?

Sent from my iPhone using Tapatalk

If that isn’t it, I’d swap the motor out and see if that makes the difference.

Have you tried cutting other materials on this machine? Are you able?

Sent from my iPhone using Tapatalk

I have done a couple of long cuts on steel but not with any real heavy cuts yet...If you have two capacitors on the motor, it could be that the run capacitor is shot. Since it starts fine, one could assume your start capacitor is fine. All of this assumes you have a two capacitor motor.

If that isn’t it, I’d swap the motor out and see if that makes the difference.

Have you tried cutting other materials on this machine? Are you able?

Sent from my iPhone using Tapatalk

- Joined

- Oct 16, 2014

- Messages

- 314

110V motors come in all kinds of HP ratings. A sewing machine motor is 110V. So are many air compressors.

You're not running 1/2 hp. That much is certain.

Or if you are, there is something very wrong with your motor and you're not *getting* 1/2 hp.

You're not running 1/2 hp. That much is certain.

Or if you are, there is something very wrong with your motor and you're not *getting* 1/2 hp.

So.. do I spend the money to take this motor and have it rebuilt by a shop??? Or.. go buy a new motor that will fit in my configuration.. same HP and speed... or.. do I take the treadmill that I have and use the motor and controller from that?? Anyone want to help me out with the pros and cons on the Treadmill motor???110V motors come in all kinds of HP ratings. A sewing machine motor is 110V. So are many air compressors.

You're not running 1/2 hp. That much is certain.

Or if you are, there is something very wrong with your motor and you're not *getting* 1/2 hp.

- Joined

- Dec 25, 2011

- Messages

- 10,511

A quarter turn on the cross feed crank is 0.025". Try 0.010". If the motor starts quickly and coasts to a stop instead of stopping instantly when you remove power, there is nothing wrong with the Start Capacitor and probably nothing wrong with the bearings. The line cord should be at least #14-3 AWG and not over about 10 feet long. #12-3 is better. And the outlet should be wired with #12-3 AWG. Unplug the line cord. Open the wiring access plate on the motor and loosen and re-tighten each screw or wire nut. Connect an AC volt meter to the two terminals that the line cord black and white wires are connected to. Plug back in the line cord. In most parts of the US, the meter will read between 118 and 125 VAC, Start the motor. The meter needle should dip momentarily but then return to the original reading. Engage the power feed. Same thing should happen. If the motor stalls and/or the line voltage drops more than 1 or 2 volts, one of three things is probably the culprit.

1 Problem in the motor

2 Problem in the lathe

3 Problem in the AC supply to the wall outlet

Do you have an AC Ammeter with at least 0-20A range?

1 Problem in the motor

2 Problem in the lathe

3 Problem in the AC supply to the wall outlet

Do you have an AC Ammeter with at least 0-20A range?

- Joined

- Oct 16, 2014

- Messages

- 314

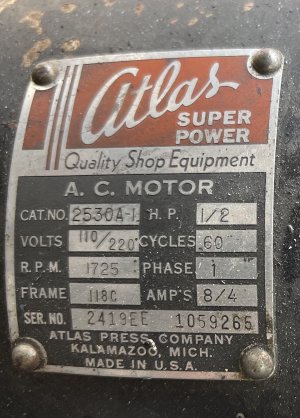

First we need to know what does your motor SAY that it is? What's the placard say? It's possible someone might've replaced it with a cheaper, smaller motor than original. It's possible you've been laboring with an underpowered setup. If not, you're just using it incorrectly, but if so, it's probably time for a replacement.So.. do I spend the money to take this motor and have it rebuilt by a shop??? Or.. go buy a new motor that will fit in my configuration.. same HP and speed... or.. do I take the treadmill that I have and use the motor and controller from that?? Anyone want to help me out with the pros and cons on the Treadmill motor???

Treadmill motor is a PROJECT. Not a great big project, but mounts and belts and wiring that all have to be fabricated; including troubleshooting.

A shop might rebuild yours cheaper than a new one. I don't know. Of course, if it's not the right spec, there's nothing to rebuild, anyway.

First we need to know what does your motor SAY that it is? What's the placard say? It's possible someone might've replaced it with a cheaper, smaller motor than original. It's possible you've been laboring with an underpowered setup. If not, you're just using it incorrectly, but if so, it's probably time for a replacement.

Treadmill motor is a PROJECT. Not a great big project, but mounts and belts and wiring that all have to be fabricated; including troubleshooting.

A shop might rebuild yours cheaper than a new one. I don't know. Of course, if it's not the right spec, there's nothing to rebuild, anyway.