Hi All,

I posted the below at the other forum, I'm tapping into the collective wisdom here as well.

Thanks, much.

Joe

Good Evening,

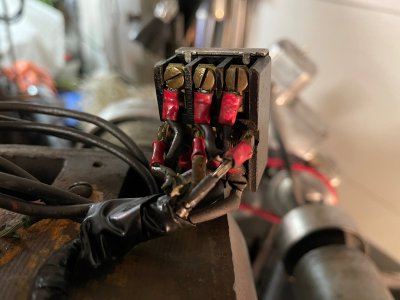

Still working on my recent acquisition of a KO Lee model B960 T&C Grinder. The toggle switch for the work head needs to be replaced and I'm not sure of a source for it hence my inquiry here. The switch mounts (photos below) to the housing using two small screws and after quite a bit of searching, I can't seem to find a drop in replacement. I'm hoping someone can point me in the right direction.

If I may, the wiring to the motor and switch is crumbling so replacement is in order. I'm not sure what kind of strain relieve is used where the wires enter/exit the motor housing. I attached a photo of that too in the hopes someone can guide me with that as well.

Many thanks and much appreciation.

Joe

I posted the below at the other forum, I'm tapping into the collective wisdom here as well.

Thanks, much.

Joe

Good Evening,

Still working on my recent acquisition of a KO Lee model B960 T&C Grinder. The toggle switch for the work head needs to be replaced and I'm not sure of a source for it hence my inquiry here. The switch mounts (photos below) to the housing using two small screws and after quite a bit of searching, I can't seem to find a drop in replacement. I'm hoping someone can point me in the right direction.

If I may, the wiring to the motor and switch is crumbling so replacement is in order. I'm not sure what kind of strain relieve is used where the wires enter/exit the motor housing. I attached a photo of that too in the hopes someone can guide me with that as well.

Many thanks and much appreciation.

Joe