- Joined

- Dec 18, 2013

- Messages

- 87

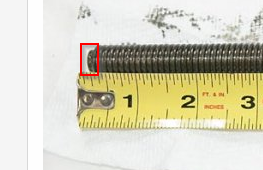

Please excuse my probable lack of the proper term but the tailstock on the 12x54 Hendey gear head I purchased earlier this year is missing the bolt that you back into and bump out the tooling.

Would anyone happen to have a diagram and/or information on how to tear this apart so I can replace this piece?

Would anyone happen to have a diagram and/or information on how to tear this apart so I can replace this piece?