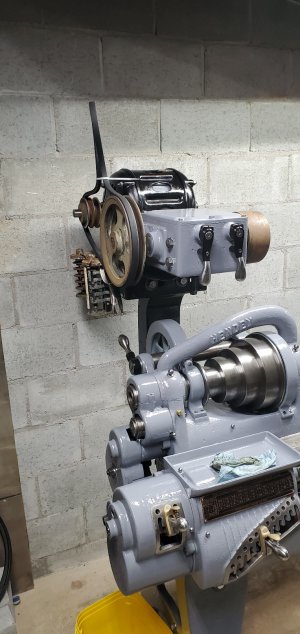

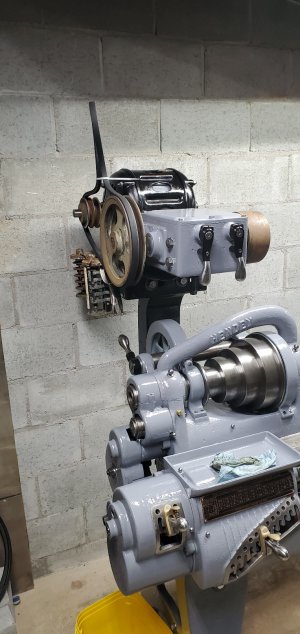

This morning I decided to start planning where to mount the motor controls. I wanted them in an out of the way but easily accessible location. I probably won't use them much, but still would like to retain their functions.

I started by setting the motor in place... (ouch- that thing is HEAVY), then installed the pulleys and mocked up a belt. I clamped the switches in place in the general area that I would like to mount them...

Everything looks pretty good. The front switch is fairly close to the belt, but has plenty of clearance considering that these switches should never be used with the motor running.

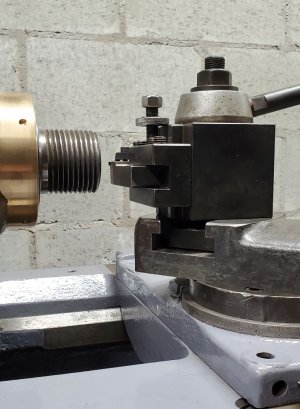

I have found a design flaw with the transmission gearbox/ flat belt tensioning...

The bolt that the arrow points to is turned to adjust the flat belt tension. It pushes up on the gearbox, which hinges on the circled pin to tighten the belt. This pin, of course, is behind the input shaft pulley.

So, as the flat belt is tightened, the v-belts from the motor to the transmission loosen...

So as you remove tension from the flat belt (which I always do when I'm finished using my lathes), the v-belts become tighter.

A happy medium will have to be found between the two... I may be overthinking this, after all, this system has obviously worked fine for many years... I'll work on that later.

I'm about to go out to the shop and smear some paint on the compound and tailstock while the weather is warm.

-Bear