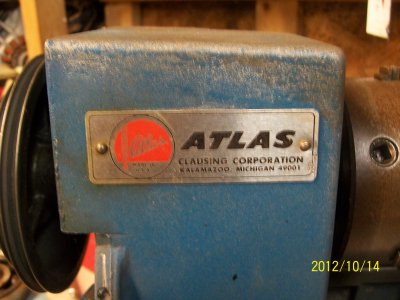

As I stated in the newbe section, Ive never used one of these, meaning a tool to cut metal, unless you call my small drill press a metal cutting tool. Any way my friends that have lathe, real big things that are 3 phase machines, said that I need to keep my eye open for a small lathe. Ive been to auctions over the years, see how long Ive been looking for a deal, but stuff was always out of reach for me. One day I came home and saw an add on CL for this, 50 bucks, I went and got it.

Now its up to you all to help me out on using this. This is the only tool I have for it, the cover is missing and people give me mixed ideas on needing change gears. Im still making room in the shop for it, have a place that I want to put it, but theres an eng there right now waiting on a part to install in a garden tractor. Im hoping by Thanksgiving I will have it mounted and running.

Can someone please tell me what tool I ave and what it is used for. Also I know I cant make my own tooling from blanks, but is there something I can but cheap, like under 100 bucks to start to learn with. Im thinking Im going to break something, well I have visions of it any way. Ive been watching a lot of Tubal Cain vidios on you tube for the basics. Many are over my head but something like the facing vid Ill watch a few times a week to get it in my head.

Thanks Vince

Now its up to you all to help me out on using this. This is the only tool I have for it, the cover is missing and people give me mixed ideas on needing change gears. Im still making room in the shop for it, have a place that I want to put it, but theres an eng there right now waiting on a part to install in a garden tractor. Im hoping by Thanksgiving I will have it mounted and running.

Can someone please tell me what tool I ave and what it is used for. Also I know I cant make my own tooling from blanks, but is there something I can but cheap, like under 100 bucks to start to learn with. Im thinking Im going to break something, well I have visions of it any way. Ive been watching a lot of Tubal Cain vidios on you tube for the basics. Many are over my head but something like the facing vid Ill watch a few times a week to get it in my head.

Thanks Vince