- Joined

- Feb 9, 2017

- Messages

- 5,240

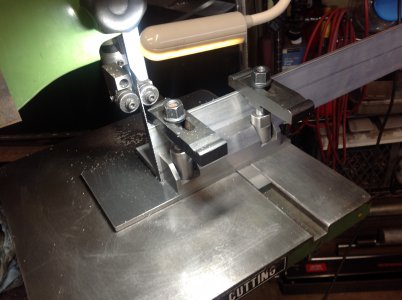

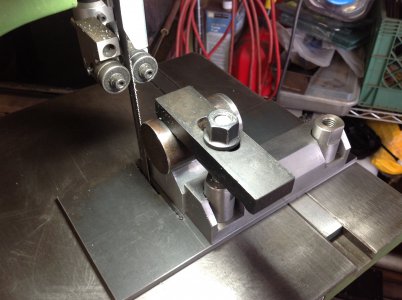

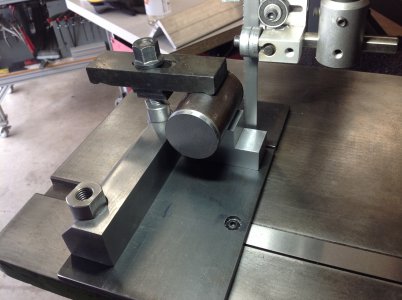

Several years ago now I decided i needed a vertical bandsaw and the cheapest most flexible option after looking into it was the HF 14” which is a direct knockoff of the Delta. The most popular version of a 14” with several places that supply parts and it’s all cast iron construction. I needed it to be for cutting metal and several places on the net said 110ft per min was good for most everything, so I looked up a conversion chart online. The 1 1/2hp motor from a donor table saw ran at 1750 so the most compact way to get it to work was a double reduction.

I had the material and the pulleys along with the table saw motor mount. Instead of the silly sliding bolted affair I opted for making using the table saw motor mount and everything thing hangs off the main upper pulley. The jackshaft, pulleys and motor all auto tension by hanging. its simple to change belts or maintenance by just pulling up on the jackshaft angle iron and pull the top belt off then lower the motor and jackshaft to the floor. No belt adjusting and it has cut through 4” blocks of aluminum, steel and cast iron with no slippage. I made the belt guard out of some perforated material I had and welded some wheels to the bottom to be able to move the saw as needed like a hand truck.

I had the material and the pulleys along with the table saw motor mount. Instead of the silly sliding bolted affair I opted for making using the table saw motor mount and everything thing hangs off the main upper pulley. The jackshaft, pulleys and motor all auto tension by hanging. its simple to change belts or maintenance by just pulling up on the jackshaft angle iron and pull the top belt off then lower the motor and jackshaft to the floor. No belt adjusting and it has cut through 4” blocks of aluminum, steel and cast iron with no slippage. I made the belt guard out of some perforated material I had and welded some wheels to the bottom to be able to move the saw as needed like a hand truck.

Attachments

Last edited: