A

Alan H.

Forum Guest

Register Today

I am not a huge Harbor Freight fan but like most, I buy some stuff there. Yes, I have the usual 2 ton shop crane and the 20 ton hydraulic press that came from there. In addition to these, one of my favorites is their tool chests. You buy them when they are on sale and even when they're not being advertised, you can likely find a coupon via Google.

I now have three of these small ones that are made to hang on the side one of their bigger models. I put wheels under them and use them as roll arounds as needed. I buy the high capacity casters on ebay. (Sorry, not a fan of HF casters).

You put some wooden spacers on the bottom to attach the casters to and you have a very stout and well supported little roll around. Here's the latest one that I bought to store some of the most frequently used lathe tooling in.

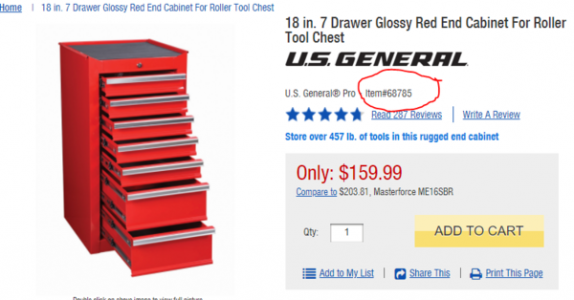

Model 68785 Chest (here's the best price I have seen for it):

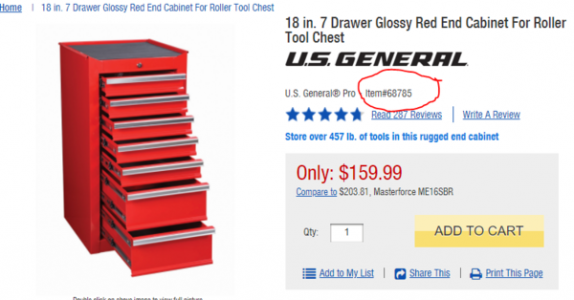

Made to hang off a bigger chest:

Here she is upside down to get the wood added the bottom for the casters. Lots of ways to skin this cat, here's mine. Front end has a lip to slid the timber under and you use the bolt holes on the ends to secure with hex head lag screws. Back side has no lip so you add a lag screw in the center as well as lag screwing the ends. A 2 x 4 screwed to a plywood spacer to get the thickness just right:

High capacity casters attached with hex head lag screws:

Here it is in its spot next to the lathe. (@wrmiller - notice the 5C chuck on top)

EDIT: If memory serves me correct, Mark (@mksj) is the one who gave me the tip on these last year. I may need one more!

I now have three of these small ones that are made to hang on the side one of their bigger models. I put wheels under them and use them as roll arounds as needed. I buy the high capacity casters on ebay. (Sorry, not a fan of HF casters).

You put some wooden spacers on the bottom to attach the casters to and you have a very stout and well supported little roll around. Here's the latest one that I bought to store some of the most frequently used lathe tooling in.

Model 68785 Chest (here's the best price I have seen for it):

Made to hang off a bigger chest:

Here she is upside down to get the wood added the bottom for the casters. Lots of ways to skin this cat, here's mine. Front end has a lip to slid the timber under and you use the bolt holes on the ends to secure with hex head lag screws. Back side has no lip so you add a lag screw in the center as well as lag screwing the ends. A 2 x 4 screwed to a plywood spacer to get the thickness just right:

High capacity casters attached with hex head lag screws:

Here it is in its spot next to the lathe. (@wrmiller - notice the 5C chuck on top)

EDIT: If memory serves me correct, Mark (@mksj) is the one who gave me the tip on these last year. I may need one more!

Last edited by a moderator: