-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

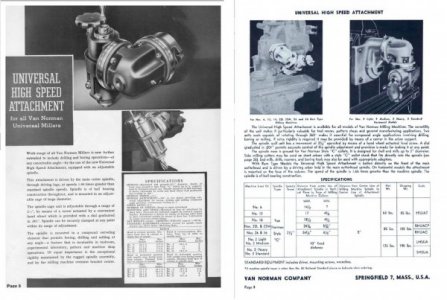

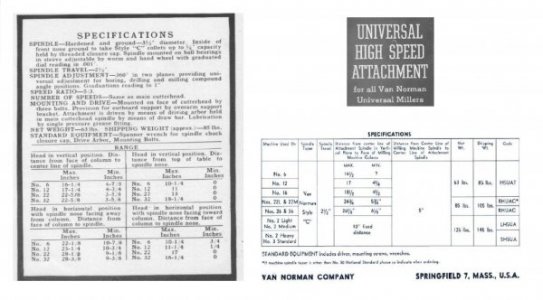

VN High Speed Sub Head

- Thread starter BROCKWOOD

- Start date

Jason had 1 of these for sale for a VN no22 because it is too big for his mill. So naturally I had to weigh the odds of whether it would fit my no24. Usually the answer would be yes - but the fine print concerning the no22 is they could be made to order so that it would fit older spindle sizes too. So, I bought it. Jason has a knack for making shipping boxes!

Previews.

For sale pic.

85 pound box came today.

Sneak peak.

Restoration & measurements coming as I can.

Previews.

For sale pic.

85 pound box came today.

Sneak peak.

Restoration & measurements coming as I can.

Looks like I can exchange the mount portion for 1 that will fit my mill & mine goes to fit another mill. Win Win. The lathe, still the brake on all my projects is getting oh so close. This is gonna be good!

Well, the friend with the correct mount portion for me has a 1R series mill. Although his mount portion will fit mine ...... mine won't fit his. Therefor we have no swap. In other news I scooped up a slotter that has the correct adaptor to fit itself & the subhead to my mill! Yeah it uses the same 22 style as my subhead & the adaptor has me in business! Documentation will be fun!!!

Last edited:

- Joined

- Jan 2, 2016

- Messages

- 1,953

Cool deal. Can't wait to see pics of it in action.

Thanks Superburban! Yeah, I keep getting closer to that glorious stage of really putting all this to work for me. I really thought "this is the year I break ground & build my shop. 2019 to resurrect a 1959 Butler Building I have laying in pieces seems fitting. Best go on & pull that 3 phase into my garage at this rate. Gotta love the kids & grandkids & && . I'm on hi center at the moment though. My lathe motor is out for a rebuild. I need to finish a tool to blow this hi speed head down to basic components for documentation / refreshing too.

I have made my mind up on 1 thing though: I'll punch through my foundation to get 1ph power out & 3ph power in. It is a house in a nice neighborhood & just 1 more hole in the brick will be too much.

Yeah, I do tend to be slow on major decisions (really wanted to resurrect my shop instead - but tired of waiting).

As an aside: Is 0.250 backlash on the table X axis excessive? Table / Knee assembly leaks too. At least the head section has held it's oil level steady!

I have made my mind up on 1 thing though: I'll punch through my foundation to get 1ph power out & 3ph power in. It is a house in a nice neighborhood & just 1 more hole in the brick will be too much.

Yeah, I do tend to be slow on major decisions (really wanted to resurrect my shop instead - but tired of waiting).

As an aside: Is 0.250 backlash on the table X axis excessive? Table / Knee assembly leaks too. At least the head section has held it's oil level steady!

- Joined

- May 15, 2019

- Messages

- 9

1/4” backlash is a lot. Hopefully you got the decimal point in the wrong place. Even still —before the internet convinced us backlash was the enemy of production, the old timers were turning out marvelous, accurate parts on machines with dished ways and 1 1/2 turns worth of backlash.

As far as oil holding, my machines are like a Land Rover — if it ain’t leakin’ It’s empty!!

As far as oil holding, my machines are like a Land Rover — if it ain’t leakin’ It’s empty!!