-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hobby milling machine

- Thread starter elewayne

- Start date

- Joined

- Mar 29, 2017

- Messages

- 737

I really like my Millrite MVN. I have not had it too long, but it is more machine than I am machinist, and will be for a time, I suspect. It doesn't take up TOO much more space than many benchtop machines, and is very rigid for the things I ask of it.

- Joined

- Mar 10, 2012

- Messages

- 1,368

I've been down the whole new vs used machines road when I was considering a mill and then lathe. Unless you have complete trust in the seller, know someone experienced with mills that can look at a used machine and give you his honest opinion, or you have enough knowledge to be able to NOT be taken, I strongly suggest you buy new. If you have to wait to save up then it'll be worth it. There's few downers in life like buying a (expensive?) machine you think is in good condition only to find out once you start using it it's pretty much a boat anchor or not tight enough to meet your standards.

Always my the biggest that fits your budget and space. Just remember, No matter how big your machines are, There will be times you wished it was a little bit bigger.

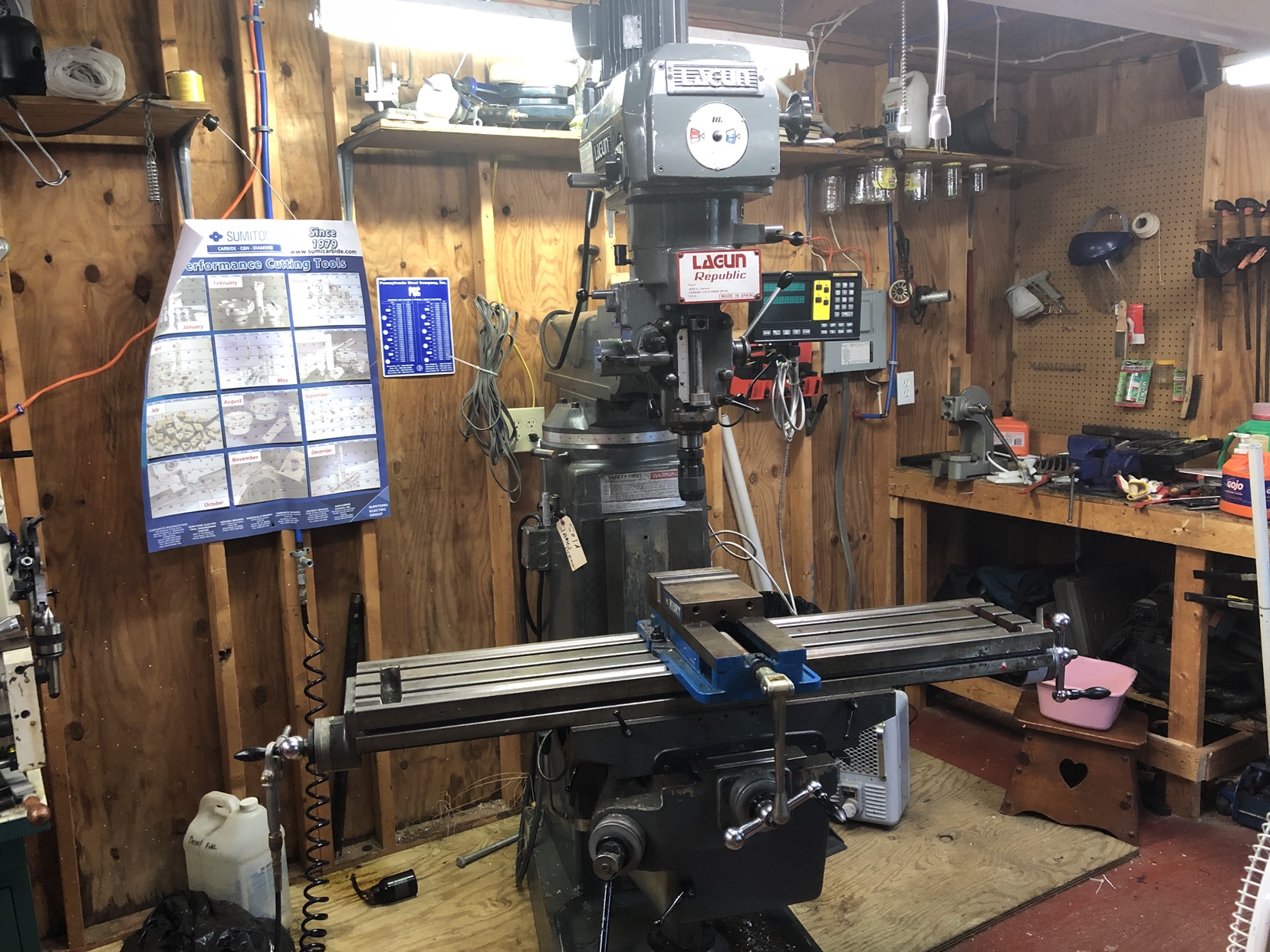

Yep when I upgraded from my PM 25 I shoehorned the biggest mill I could fit in my shop

Sent from my iPhone using Tapatalk

Jumping on this Bandwagon.

I too am find myself considering a hobby mill. Additionally, I would like to look at purchasing a lathe as well.

I get the feeling that Precision Matthews makes the best available entry level Mill. They are in Pittsburgh, Pennsylvania - a short 5 hour trip from where I live. I read their FAQ's and would plan a visit before purchase.

I ask which machine would be a good fit for my needs.

I am:

1. Completely new to Machinist work; I have taken basic Mill operation only.

2. I am interested in doing only hobby work and maybe OAK pieces of art in T6061. Any harder materials would rarely used - occasional projects to

make cutters or tools for the workshop or lathe.

3. My project will more than likely always be smaller than a breadbox - 12" x 6" x 6".

3. I have a fairly healthy budget for a hobby interest - $3000.

4. Space - my limiting factor. I would prefer to keep the mill in a 24"x 36"x 96" space.

5. Considering a Dividing plate with a tail stock or rotary table for circular pieces.

Which PM machine would you get? I have little interest in mass production. CNC seem of little use to me. Digital read outs seem a reasonable desire.

Thoughts?

Thanks,

Clint

I too am find myself considering a hobby mill. Additionally, I would like to look at purchasing a lathe as well.

I get the feeling that Precision Matthews makes the best available entry level Mill. They are in Pittsburgh, Pennsylvania - a short 5 hour trip from where I live. I read their FAQ's and would plan a visit before purchase.

I ask which machine would be a good fit for my needs.

I am:

1. Completely new to Machinist work; I have taken basic Mill operation only.

2. I am interested in doing only hobby work and maybe OAK pieces of art in T6061. Any harder materials would rarely used - occasional projects to

make cutters or tools for the workshop or lathe.

3. My project will more than likely always be smaller than a breadbox - 12" x 6" x 6".

3. I have a fairly healthy budget for a hobby interest - $3000.

4. Space - my limiting factor. I would prefer to keep the mill in a 24"x 36"x 96" space.

5. Considering a Dividing plate with a tail stock or rotary table for circular pieces.

Which PM machine would you get? I have little interest in mass production. CNC seem of little use to me. Digital read outs seem a reasonable desire.

Thoughts?

Thanks,

Clint

- Joined

- Jun 12, 2014

- Messages

- 4,806

Probably the PM-30MV, mid size, belt drive (quiet), good power and torque from the 2Hp DC motor with variable speed to 3000 RPM. Running 230V will give better power, but requires that this is available, if only 120VAC then the PM-727V is a great choice. This also leaves a budget for a 2 axis DRO, vise and tooling. The 932/940 are much heavier but lower speed, probably more optimal for larger work scope, deeper cuts and ferrous metals. If this is a long term machine (investment) and you want a high quality bench top mill, I would check out the PM-833T. Buy once, cry once.

Anyone of these mills will chew through aluminum at a good rate, if you use a rougher end mill the chips will fly at an amazing rate. I would also consider an X power feed, this will give much better consistent finish and you get tired of hand cranking quickly.

Good luck

Mark

Anyone of these mills will chew through aluminum at a good rate, if you use a rougher end mill the chips will fly at an amazing rate. I would also consider an X power feed, this will give much better consistent finish and you get tired of hand cranking quickly.

Good luck

Mark

- Joined

- Jul 28, 2017

- Messages

- 2,366

I got an SX2 from Micro-Mark when it was on sale. It has an R8 spindle so the tooling I have can be used on a larger machine if I ever go that route. Many would say this class of machine is a kit of sorts, but you can use the mill itself to make many improvements to it. One of the first ones I did was to add DROs to all 3 axes. I have learned a lot with mine, misteaks and all <grin>. If you do decide it's too small for you, you can always sell it (but don't expect to get more than about 50% of what you paid for it).

I have found the old adage of spending as much, if not more, on tooling to be pretty accurate. So getting something that allows you to migrate most of your tooling to a larger machine makes a lot of sense.

Mark

I have found the old adage of spending as much, if not more, on tooling to be pretty accurate. So getting something that allows you to migrate most of your tooling to a larger machine makes a lot of sense.

Mark

If I lived in Houston... I'd be checking Craigslist. Heck...I drove to Houston to buy my 9A South Bend 3-1/2' bed. You have a lot of good machine tools always popping up in your area. Of course, to each their own. Some prefer new, but my wallet prefers used.