I’ve got Mark’s 3 jaw set-tru and a Bison 4 jaw for my 1340GT. On my South Bend I could hold small diameter material in the chuck easily but these chucks can’t close small enough. Obviously, there are collets but changing chucks out is more time consuming than I’m after. Are there any options for holding small work and then holding that in the larger chucks?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Holding Small Material

- Thread starter parshal

- Start date

- Joined

- Jul 8, 2018

- Messages

- 880

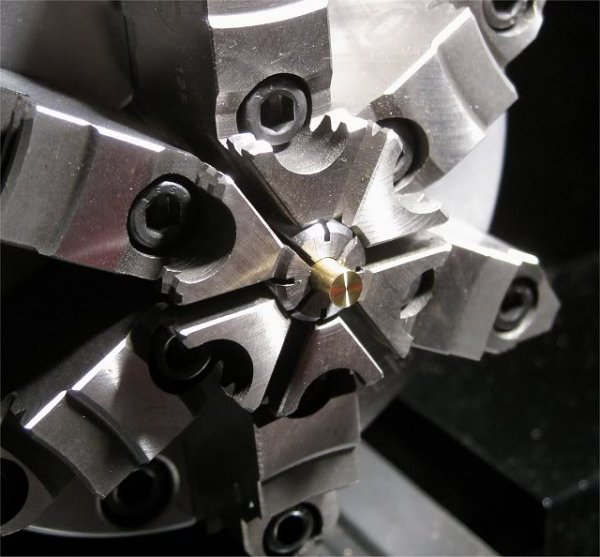

Grip the smaller south bend chuck in the larger bison chuck

- Joined

- Nov 27, 2012

- Messages

- 7,854

I use DA collets to hold small stock in my 6-jaw chuck as it can only clamp down to about 1/4" with all 6 jaws in. They're similar to ER collets as they are designed for tool holding & aren't good for clamping very short pieces like 5C collets can. I rarely have a problem but when I do I just put a piece of stock of the same diameter behind the work piece if it's too short to hold securely. Much quicker than removing 3 of the jaws or swapping chucks and doesn't introduce any discernible runout.

The pics are from my old mini lathe as I've been using this method for quite some time but I use the same method quite often with my current lathe.

I also have a 2.5" 3-jaw chuck that I made a straight shank for to hold in my chuck but it's a cheap chuck & the runout sucks. I've been meaning to grind the jaws but it's not important to me, the DA collets serve me well.

I also have a DA collet holder but the face of the collet does not sit flush with the end of the collet nut like ER collets so I don't use it that often.

The pics are from my old mini lathe as I've been using this method for quite some time but I use the same method quite often with my current lathe.

I also have a 2.5" 3-jaw chuck that I made a straight shank for to hold in my chuck but it's a cheap chuck & the runout sucks. I've been meaning to grind the jaws but it's not important to me, the DA collets serve me well.

I also have a DA collet holder but the face of the collet does not sit flush with the end of the collet nut like ER collets so I don't use it that often.

Make a bushing with a reamed hole if possible. Tiny stuff adds difficulty for sure with Concentricity. One slit to the hole and two other slits not to the hole but more than half of the material thickness from i.d to o.d.. All evenly spaced spaced ready for your three jaw.

How tiny?

How tiny?

Good ideas to think about.

Yesterday I was making a cross slide screw lock and needed to cut a .234" piece of steel rod for a handle. That's when I realized how much smaller stuff I cut regularly on the old lathe. I had to take out a hacksaw and, of course, cut it twice!

Yesterday I was making a cross slide screw lock and needed to cut a .234" piece of steel rod for a handle. That's when I realized how much smaller stuff I cut regularly on the old lathe. I had to take out a hacksaw and, of course, cut it twice!

- Joined

- Mar 21, 2013

- Messages

- 4,063

I have a straight shank ER collet chuck that I occasionally chuck up in my 8" PBA for quick and dirty. But to be honest it doesn't take that much more time to throw my 6" set-tru collet chuck on the lathe. Especially if I need to dial the chuck in for minimal TIR.

I'll look into the ER collet chuck. When I was doing this yesterday, everything I was cutting was large enough for the larger chuck. I then had a one-off need to cut a small piece. Swapping out the chuck and dialing it in to part off the part would have taken far too long. I need a quick and dirty method.

- Joined

- Nov 5, 2016

- Messages

- 1,419

I've been using my Albrecht chucks (ones mounted on 1/2" straight shanks) in my 1/2" collets to hold small pieces I don't have the correct collet size for... works great! No through hole so the piece has to be short, but it works for shorter pieces.

Ted

Ted

Something like this would be quick and dirty in the 3-jaw.

HHIP 3900-5129 Hex ER-40 Collet Block: Amazon.com: Industrial & Scientific

HHIP 3900-5129 Hex ER-40 Collet Block: Amazon.com: Industrial & Scientific

www.amazon.com

Amazon.com: Accusize Industrial Tools 23 Pc Er40 Collet Set, Size from 1/8'' to 1'' in Fitted Strong Box, 0223-0935: Industrial & Scientific

Buy Accusize Industrial Tools 23 Pc Er40 Collet Set, Size from 1/8'' to 1'' in Fitted Strong Box, 0223-0935: Collets - Amazon.com ✓ FREE DELIVERY possible on eligible purchases

www.amazon.com

Last edited: