-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hole Depth (drill Depth)

- Thread starter tomw

- Start date

- Joined

- Jan 24, 2015

- Messages

- 239

Ray,

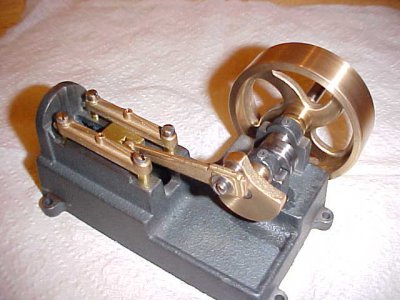

Thank you for the welcome. I am building the PM Research steam engine #3

The drawings are great, but they just call out "Drill #38 3/4 depth" for example. Thus my question about generally accepted standards for hole depth on a drilled holed. My wife belongs to a band called the Minor Mishap Marching Band. Because of several small errors so for, I am naming my first project in their honor. I am also painting it the band colors (yellow and black).

Thank you for the welcome. I am building the PM Research steam engine #3

The drawings are great, but they just call out "Drill #38 3/4 depth" for example. Thus my question about generally accepted standards for hole depth on a drilled holed. My wife belongs to a band called the Minor Mishap Marching Band. Because of several small errors so for, I am naming my first project in their honor. I am also painting it the band colors (yellow and black).

- Joined

- Jan 13, 2015

- Messages

- 52

Thank you all for your responses. The drawing I am working off of (a steam engine kit) does not specify shoulder or full depth (A or B), so I thought there might be a convention. It seems like maybe there isn't. I guess I will go to B, and if it is not deep enough go to A.

drill baby drill

- Joined

- Jul 20, 2014

- Messages

- 1,386

I have a similar situation with counter bored holes, so I will use an end mill for the counter bore. I use end mills for drill or finishing a hole to size when I want a

flat bottom. You can also grind a flat bottom drill. I'm still trying to learn to do this. Anything else, I always calculate the entire drill to the point. i.e. blind holes

Of course, there is also the boring head.

flat bottom. You can also grind a flat bottom drill. I'm still trying to learn to do this. Anything else, I always calculate the entire drill to the point. i.e. blind holes

Of course, there is also the boring head.