B

Bill Gruby

Forum Guest

Register Today

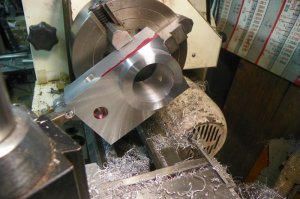

I indicated it in the bore Andy. Every moving part centers on the bore of this part. It is essential that it is true.

"Billy G"

"Billy G"

Dan;

The set up maxed my lathe out. This is the largest I can do using the 4 jaw offset. But yes it did it well. The lathe was running at 800 RPM. Six light cuts cleaned it up.

"Billy G"