- Joined

- Nov 1, 2018

- Messages

- 98

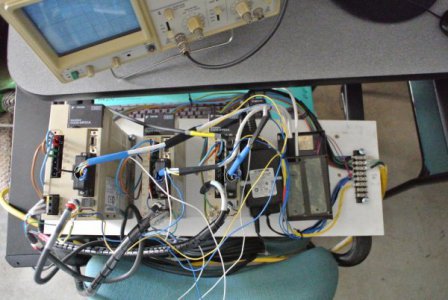

I used SigmaWin+ tool to configure and auto-tune my servodrives. This tool is available for free download on Yaskawa website, as well as all manuals. This tool allows to:

1. check the drive,

2. configure it to one of the standard settings (velocity, torque, position, combined mode, etc.),

3. auto-tune electromechanical control loop,

4. check the Gain, stability and Phase Margin of the loop,

5. automatically search and suppress electromechanical resonances (tool performs FFT analysis and enables notch filters),

6. apply hundreds of settings, limits, adjustment manually.

I use these steps above to setup and configure my Sigma-3 servodrives as a part of the lathe. As I know auto-tuning is not available on older Sigma-1 and Sigma-2 generations. The next Sigma-5 and Sigma-7 gens are much more powerful!

What is really great about SigmaWin+, that it analyzes the performance of the whole machine! (mill, lathe, plasma cut), considering servodrives as parts of the bigger system. The tool tunes-up the servodrives to a machine-specific rigidity, inertia, friction, step-response to provide the best performance in each individual case. Even my Z and X drives have different settings after auto-tuning, because the weights and rigidity of Z and X axis’s are different.

Yaskawa manuals are very technical, detailed and clear. These are one of the best manuals I’ve ever seen. JZSP-CMS02 cable to connect servodrive to PC is available on ebay.

1. check the drive,

2. configure it to one of the standard settings (velocity, torque, position, combined mode, etc.),

3. auto-tune electromechanical control loop,

4. check the Gain, stability and Phase Margin of the loop,

5. automatically search and suppress electromechanical resonances (tool performs FFT analysis and enables notch filters),

6. apply hundreds of settings, limits, adjustment manually.

I use these steps above to setup and configure my Sigma-3 servodrives as a part of the lathe. As I know auto-tuning is not available on older Sigma-1 and Sigma-2 generations. The next Sigma-5 and Sigma-7 gens are much more powerful!

What is really great about SigmaWin+, that it analyzes the performance of the whole machine! (mill, lathe, plasma cut), considering servodrives as parts of the bigger system. The tool tunes-up the servodrives to a machine-specific rigidity, inertia, friction, step-response to provide the best performance in each individual case. Even my Z and X drives have different settings after auto-tuning, because the weights and rigidity of Z and X axis’s are different.

Yaskawa manuals are very technical, detailed and clear. These are one of the best manuals I’ve ever seen. JZSP-CMS02 cable to connect servodrive to PC is available on ebay.